Authored by Abdelbary A*

Introduction

Artificial joint replacement is one of the most essential arthroplasty for sever diseases of human joints. This surgical treatment involves the replacement of native articulating joints, such as the knee, hip, ankle, and shoulder with artificial components. Currently, it is assumed that there are well over one million artificial joints implanted yearly into patients world-wide [1,2]. By 2030, there may be 500, 000 total hip arthroplasty (THA) and 3 million total knee arthroplasty (TKA) cases per year [3,4]. Various biomaterial combinations include metals, ceramics, carbon and synthetic polymers are now used in biomedical applications.

In particular, polymeric materials have shown a greatest success in this field due to its excellent tribological properties. Low friction coefficient, high wear resistance, compatibility of wear debris with the body, compatibility of being sterilized by γ-irradiation, and the facility to operate efficiently for long time under no maintenance conditions are the factors that have made it a highly successful bearing material in these applications [5-8].

For several decades’ polyethylene has remained the most suitable material choice for the articulating surface in total joint replacements [9-11]. UHMWPE used as an acetabular cup where the femoral head was stainless steel, ceramic or alumina. UHMWPE was first introduced by Charnley J [12,13] as an alternative for the failed previous polytetrafluoroethylene (PTFE), because the superior wear resistance of the former. A new type of polyethylene material has been developed recently which shown excellent wear properties compared to UHMWPE. This material has been named as ultra-low wear polyethylene (ULWPE). In addition, ULWPE has excellent wear resistance, which is also easy to process [14].

Friction, wear and lubrication of artificial joints play important roles in its successful function. However, it is unpredictable due to complex tribological and biological behaviours and long-term wear [15]. Research efforts are currently addressing the evaluation of the determinants affecting the overall wear rate of the artificial joint articulating surfaces, with the aim of reducing wear rate. However, one of the main challenges is the translation of research data from in vitro to in vivo environments [16]. For example, the wear debris produced by the hip joint simulator has a larger average size and wider distribution range compared to those from the implanted artificial joint [17]. The average diameter of the wear debris from joint simulator is 7.54 μm. The average diameter of the wear debris from artificial joint is 1.33 μm (about 18% of the wear debris from joint simulator).

In order to study the failure criteria of artificial joints, a pioneer work was done by Atkinson [13] based on the investigation of a number of worn hip joints ranging in age from 1- 12 years. They observed that the wear and deformation processes of the acetabular cups seemed to be as follows:

1. Initially, a running-in period: the entire cup surface wears abrasively.

2. With increasing mobility, the upper half of the cup wears adhesively.

3. After several years’ wear, fine fatigue cracks formed on the wear area.

Many questions which need answering were recognized:

Are any of the observed wear feature likely to enhance early failure of the acetabular cup or are there other possible mechanisms?

Are the surface fatigue cracks going to be deletrious? Will they shorten the useable lifetime of the cup?

What is the effect of the cyclic loading on the failure resistance and surface cracks of the polymeric material specially in fluid lubricated media?

What is the effect of the generated wear particle size on the clinical infection?

Finally, it was reported that no conclusions could be drawn, and further researches are necessary. For more than four decades, to the best of our knowledge, hundreds of researches were established in order to find answers for those questions. The present paper is aimed to review and argue the failure criteria of artificial joints.

Tribology of Artificial Joints

Tribology has a significant role in the functioning of artificial joints. General fundamentals of tribology can be used to understand the friction, lubrication and wear of natural and artificial joints in the body [18]. Friction played a dominant role in the design of original Charnley low-friction arthroplasty [19]. Also, wear has an important role, not only from the integrity of the prosthetic component point of view, but also from that of wear debris which can cause adversely biological reactions [15]. Finally, both of friction and wear can be reduced effectively by lubrication.

Friction

In his low-friction arthroplasty, Charnley, J. introduced the significance of friction in the design of artificial joints [12]. At first, McKee-Farrar introduced metal-on-metal hips. Then, polytetrafluoroethylene (PTFE) was selected for its lowest frictional coefficient, although massive wear was subsequently found with the cups made of this material. Charnley preserved with polymer on metal combinations to maintain low frictional torques and introduced UHMWPE cups sliding on stainless steel femoral heads. This combination of materials has proved to be extremely successful giving low friction, low wear rates of the UHMWPE and smaller amounts of wear debris, which could be more readily tolerated by the body [10,11,20,21].

The following three laws of dry friction are often defined:

1. The force of friction (F) is directly proportional to the applied load (W).

2. The force of friction (F) is independent of the apparent area of contact.

3. The kinetic force of friction (F) is independent of the sliding speed (V).

Kinetic friction is quantified through a coefficient, the coefficient of friction (COF) f, defined as the ratio between the magnitudes of the tangential/friction force F and the normal force N at the interface, therefore:

It is worth noting the peculiar behavior of a revolute/spherical joint with frictional contact, shown in Fig. 1 [22]. If we consider a pin rotating within a collar with constant angular velocity ω, under a load W through the center of the pin itself. In a smooth contact, the equilibrium of the pin is guaranteed by a normal (radial) force N = - W applied at the contact point K on the line of action of W. If friction cannot be neglected, the total contact force at the interface R, still with the same magnitude of W, is the sum of two components N and F, respectively normal and tangent to the surface at the contact point. Thus, in this case, K is shifted backwards in an angle φ= arctan(f), so that R restrains the motion and a torque Mf must be introduced to maintain the pin rotation (Figure 1).

Wear mechanisms

Wear is recognized as the main reason of implant failure, causing inflammatory reactions and osteolysis, which can lead to implant loosening. The fundamental wear mechanisms in artificial joint are adhesion, abrasion, creep and fatigue. However, pitting, scratching, burnishing and delamination on retrieved total condylar knee joint replacements are also detected [23]. Wear depends on many factors so it can be rather hard to predict which mechanism will affect the sliding bodies. This is done usually a posteriori and in many cases several types of wear are detected. The basic wear mechanisms used to describe the wear process in artificial joint replacements are [24]:

Abrasive wear: Abrasive wear is due to the action of hard particles or asperities that plough the softer counterpart. The debris size is of a similar magnitude to the surface roughness of the harder component. Adhesive wear, in which when local welding between asperities occurs, subsequently broken in the movement.

Surface fatigue: Surface fatigue is due to repeated stress cycles in the subsurface material, which can be the onset of microcracks and debris detachment. Fatigue wear can also occur on a macroscopic scale in the form of delamination. This occurs under cyclic loading when the stress applied to the material exceeds the material’s fatigue strength [25]. Adhesion and fatigue wear work together, with the surface asperities of the two surfaces momentarily sticking together causing shear stresses that, over time, lead to the eventual fatigue of the asperity; wear particles are generally larger than those that occur in abrasive wear [18].

Pitting: Pitting has long been associated with fatigue damage and commonly has been observed in retrieved implants sterilized with gamma radiation in air, especially tibial plateaus [26]. Pitting was observed in many of the retrieved implants in the present study, suggesting that fatigue wear mechanisms may have been active in these devices. Additionally, some specimens revealed evolution of the machining marks that was suggestive of fatigue crack growth striations, as shown in (Figure 2).

Cooper [27,28] studied the wear of UHMWPE sliding on metallic and ceramic counter faces under wide range of tribological conditions in order to investigate the influence of contact stresses on the macroscopic and microscopic wear mechanisms. The studies were conducted in pin-on-disc and pin-on-plate tribometers, hip joint simulators, and retrieve artificial joints taken from patients. In the body under cyclic loading, the macroscopic polymer asperity is cyclically deformed at the frequency of the loading cycle and this can produce crack propagation and surface fatigue within 10 μm of the surface under the polymer asperity. It is likely that cyclic loading is one of the main factors affecting failure of artificial joints. Under dynamic loading conditions found in artificial joints, subsurface cracking was found in the highly strained region. Subsurface crack propagation may well have accelerated the failure and removal of material from the highly strained polymer peaks, hence greatly increasing the macroscopic polymer asperity wear processes. These processes were not only important with respect to the increased volume wear debris produced but may also produce large wear particles which can cause adverse tissue reactions in the body.

Lubrication

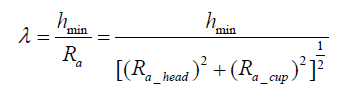

In general, lubrication refers to the existence of a lubricant between two surfaces in contact to avoid or reduce the interaction between their asperities. In healthy natural joints, synovial fluid is generally present as a lubricant. After joint replacements, a pseudo-periprosthetic synovial fluid is found to be similar to those from patients with osteoarthritis [29]. It is important to reduce the contact stresses in order to avoid failure of artificial joints, particularly for thin polymer cups. Effective lubrication, in terms of both boundary and fluid- film lubrication, is the key to reducing friction and wear in artificial joints [19]. The lubrication regime can be assessed either experimentally (ultrasound measurements) or theoretically. The theoretical assessment is based on the determination of the parameter λ defined as the ratio between the minimum film thickness hmin and the composite roughness of the two surfaces [30,31]:

where Ra is average roughness. Therefore, if a representative minimum film thickness is estimated and the surface roughness parameters are measured, the lambda ratio and the corresponding lubrication regimes can be determined accordingly:

Boundary lubrication: λ <1

Mixed lubrication: 1 < λ < 3

Fluid film lubrication: λ > 3

In joint bearing types, metal on polymer is considered to be boundary lubricated as the relatively soft polymer surface has a high roughness (~1 μm), hence surface asperity contact and wear cannot be avoided. Polyethylene does get polished or burnished in vivo which can reduce its roughness, however, the film thickness generated is insufficient to provide significant benefit. Metal on metal joints are generally considered to operate in the mixed lubrication regime. It is suggested that increasing the bearing radii, whilst keeping the radial clearance low, has been shown to increase the predicted film thickness in metal on metal hip prostheses sliding them down the slope of the Stribeck curve (Fig. 2) towards the fluid film lubrication regime [32].

Ceramic on ceramic bearings, compared to metal or polyethylene, are extremely hard and as such can be polished to a very fine surface finish (~ 0.004 μm Ra). The superior manufacturing tolerances of these bearings result in a reduced radial clearance (~ 0.04 μm) which when combined with the low surface roughness leads to a predicted fluid film lubrication regime during walking [33]. In contrast to the former findings, Abdelbary et al. [34] found dramatic increase in the wear rate of Polyamide sliding against stainless steel in water lubrication condition up to about 3 to 6 times those found in dry sliding condition, as shown in (Figure 3).

To read more about this article...Open access Journal of Archives in Biomedical Engineering & Biotechnology

Please follow the URL to access more information about this article

To know more about our Journals....Iris Publishers

No comments:

Post a Comment