Authored by Negussie F Bussa

Yoghurt contains beneficial bacteria that

confer health benefits to the consumer. Yoghurt combined with papaya

juice may

result in a product with enhanced functional and nutritional properties,

and sensory acceptability. Papaya possesses antioxidant

properties as it is rich in β-carotene and phenolic compounds. The

objective of this research was to investigate the effect of

papaya juice supplementation and levels of gelatin addition on

physicochemical and acceptability of yoghurt. The experiment was

laid out in a 3×4 full factorial arrangement where each of three gelatin

addition levels (0.5, 0.6 and 0.7% w/v of the milk) were

combined with one of the four papaya juice addition levels (0,10,15 and

20% w/w of the base milk) to give twelve different yoghurt

formulations. Proximate composition, total phenolics, total carotenoids

and reducing power of yoghurt samples were determined

on day 1 whereas yoghurt firmness and consumer acceptance tests were

done on day 7. The addition of papaya juice to yoghurt

formula resulted in a decrease in fat and an increase in the total

solids, protein and ash values. The addition of gelatin improved

the syneresis and firmness of yoghurt. Increased amount of gelatin and

papaya juice addition significantly (P≤0.05) decreased the

syneresis of yoghurt samples and increased the firmness. The total

carotene, phenolic and reducing power of yoghurt samples were

significantly (P≤0.05) increased with the increased papaya juice level.

Panelists favored samples with 10% papaya juice and 0.5%

gelatin in terms of appearance, color and overall acceptability. The

results indicated the viability of commercially producing papaya

juice supplemented yoghurt along with gelatin to combat syneresis,

improve firmness, enhanced the total carotenoids, phenol and

reducing power, crude protein and total solid of the yoghurt samples.

Therefore, it is concluded that addition of papaya juice into

yogurt improves the nutritional and functional property of yoghurt.

Keywords: Yoghurt; Nutrition; Gelatin; Papaya juice; Syneresis

Introduction

In Ethiopia, a significant proportion of milk is consumed in

the form of Ergo were the fermentation process is usually natural

[1,2]. Yoghurt production is a well-controlled process that utilizes

pure cultures of lactic acid bacteria, which are responsible for the

fermentation process.

Yoghurt is a healthy and delicious food due to its high nutritive

and therapeutic value [3]. Generally considered as a safer product

and well known and most popular worldwide [4,5].

The associations of fruits with cultured dairy products have

created healthy perceptions in the consumers mind. Papaya fruit

provides health benefits because it is sources of vitamins, minerals,

antioxidants and dietary fibers [6].

It has nutritional, medicinal, and pharmacological and a

therapeutic effect on the human body [7]. Milk is rich in protein

and fat, but it is deficient in vitamins and fiber. Thus, blending milk

with papaya juice for yoghurt would produce a nutritionally rich

functional food.

Gelatin enhances the viscosity, influence texture, creaminess

and mouth feel as well as prevents separation of whey from yoghurt

[8]. Considering the above, the production of a functional yoghurt

with papaya juice. Is an alternative for the increasing market of

health-conscious consumers and may contribute to an increase

in the vitamins and mineral consumption? The objectives of the

present work were to develop cow’s milk yoghurt added with papaya juice and gelatin and to study the physical and nutritional

properties as a function of the levels of papaya juice and gelatine.

Materials and Methods

The experiment was conducted in the laboratory of the Food

Science, and Dairy laboratory, Haramaya University. Fresh whole

cow’s milk was collected from Haramaya University dairy farm.

Fresh papaya was purchased directly from a farmer’s field. The

milk and papaya juice were analyzed for proximate compositions.

Gelatin with 240 Blooms manufactured in Brazil by Bake Mate) was

purchased from supermarket, Addis Ababa, Ethiopia. Freeze-dried

yoghurt starter culture (YC-X11 CHR HANSEN), was purchased

from chemical supplier, Yomex- import and export, Addis Ababa,

Ethiopia.

Yoghurt production

Prior to yoghurt preparation all equipment used for yoghurt

manufacturing were sterilized in autoclave after thoroughly

washing them. A freeze-dried yoghurt starter culture was used to

inoculate fresh milk 1lt, which had been heated at 90 °C for 30 min.

and immediately cold to 45 °C. The inoculated milk was incubated

at 43 0C until pH 4.6 was attained, then stored overnight at 4 °C

and then used in the yoghurt preparation. Three different blends

of gelatin at a level of 0.5, 0.6 and 0.7% with sugar at 4% milk base

were prepared. The fresh milk 3x4L was preheated to 50 0C to

facilitate melting of gelatin and uniform mixing of ingredients.

The mixes were pasteurized at 90 °C for 30 minutes and the

three premixes each was further divided into four equal portions

and in each portion papaya juice (at a level of 0, 10, 15 and 20%

(w/v) was added and then rapidly cooled to 45 °C. The inoculated

milk was added at the rate of 0.03% served as starter culture into

each mix. The resulting 12 different yoghurt formulations were

further divided into three each coded screw capped glass jars and

a temperature of 43 °C was maintained throughout the incubation

period until the pH of the control yoghurt reached 4.7.

The yoghurt samples were transferring to a refrigerator at

4 °C and then taken out and left at room temperature prior to

analyses. The samples were then homogenized to obtain a uniform

mixture for further analysis. Physico-chemical, total phenolics and

carotenoids of yoghurt samples were determined on day1 whereas

yoghurt firmness and consumer acceptance tests were done on day

7.

Physicochemical analysis

The papaya juice, fresh milk and yoghurt samples were

analysed for moisture by oven- drying method crude fat using the

Mojonnier method, crude protein using Kjeldahl method and ash by

furnace-drying [9]. The total soluble solid content was determined

with a refractometer (Hanna H1 96801, USA). The carbohydrate

and calorie values were obtained by calculation.

A firmness analysis was performed with a texture analyser, TAXT2

model using an Expert Software version 1.05 (Stable Micro

Systems, Surrey, UK). The analytical method was modified from

[10]. An aluminium cylinder probe P36R with a diameter of 35mm

was used. A compression strain of 60% was used with a 5 kg load

cell at a speed of 5mms

-1. The firmness of the yoghurt samples was

measured in triplicates.

Syneresis of the homogenised yoghurt was determined by

placing the no. 1 Whatman filter paper in a Buchner funnel. The

funnel was then placed in an Erlenmeyer flask and attached to a

vacuum pump (Fisher Scientific, FB 70155). A total of 20g of each

yoghurt samples was then spread evenly on the filter paper and

vacuum-filtered for 10 min. The collected residue was weighed

and percent syneresis was calculated by dividing the weight of the

residue by the initial sample weight multiplied by 100 [11].

Total phenolic, carotenoids and reducing power

The total phenolic content of the papaya juice and yoghurt

samples was determined using the DCPIP titrimetric method [9].

The standard used was a solution of 100 mg gallic acid diluted with

3% HPO3: HOAC to 100 ml in a volumetric flask. The dye solution

was prepared by dissolving 50 mg 2, 6-dichloroindophenol in hot

water containing 42 mg sodium carbonate. A total of 10 g each of

the sample was then added to 3% HPO3: HOAC and filtered with no.

42 Whatman filter paper. The sample extract was titrated against

the dye solution to a pink colour endpoint lasting for 15 sec. The

extract obtained was used for Spectrophotometric analysis of total

phenolics and reducing power. All of the analyses were run in

triplicate.

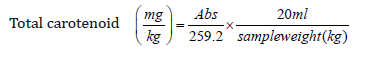

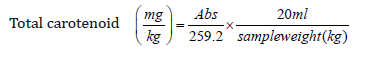

Total carotenoids content of papaya juice and yoghurt samples

was determined according [12-15]. Papaya juice sample (1g)

and yoghurt samples (5g) were mixed with 37.5ml methanol

and 12.5ml of 50% Potassium hydroxide solution in a flask for

saponification. Then unsaponifiable materials were extracted

twice with Diethyl ether (20 ml each time) and the ether extract

was washed twice with distilled water (40 ml each time). Next, the

extract was dried over anhydrous sodium sulfate. The diethyl ether

was evaporated on steam bath and the dried residue was then redissolved

in petroleum ether (20 ml). The yellow to orange color of

the petroleum ether was measured at wavelength of 450 nm with

a Spectrophotometer. The Total Carotenoids content of samples

were computed using the formula shown below and the result was

reported in mg equivalent of β- carotene per kg of papaya juice.

Where: Abs= absorbance reading, 259.2=extraction coefficient

of β-carotene in petroleum ether

20ml= volume of petroleum ether used to dissolve carotenoids

extract.

Sensory evaluation

Twenty-five panellists (13 males and 12 females from Haramaya

University) were purposely selected for sensory evaluation. A

hedonic form with a 9-point scale was given to each panel. The yoghurt samples were served in randomised order in small cups

coded with three random digits. The hedonic form scales ranged

from 1, representing ‘dislike very much’, to 9, representing ‘like very

much’. The sensory parameters used were color, appearance, body

and texture, flavor and over all acceptability.

Statistical analysis

All data were analysed using SPSS version 17.0 for Windows

(SPSS Inc., Chicago, IL, USA) with a one-way analysis of variance

(ANOVA). A Duncan’s multiple range tests was used to analyse the

differences between the individual means at a 5% significance level.

Results and Discussions

Chemical analysis of milk and papaya juice

Quality of Milk and papaya used for yoghurt production was

analysed before use. Moisture, total solid, fat, protein, ash, acidity,

pH, and solid-non-fat (SNF) were determined. Results of chemical

analysis of milk and papaya are shown in (Table 1 & 2). The results

were more or less similar to earlier studies, [16-18], respectively.

Physical and nutritional properties of papaya yoghurt

The results of the proximate composition, Total phenolics, Total

carotenoids, reducing power, Texture analysis (yoghurt firmness)

and syneresis of the yoghurt samples are presented and discussed

in the subsequent sections.

Proximate composition of yoghurt

Total solids content, moisture content, crude protein, fat, ash

and solids-not-fat of yoghurt samples were ranged from 16.29±0.06

to 16.85±0.19%, 83.04±0.05 to 83.79±0.09, 3.02±0.01 to

3.24±0.08, 2.86±0.09 to 3.16±0.09%, and 0.71±0.01 to 0.74±0.01%

and 13.04±0.29 to 13.96±0.09%, respectively (Table 3). The total

solids, protein, solid-not-fat, and ash contents of papaya added

yoghurt were higher than in control (without papaya) yoghurt. The

fat content of papaya added yoghurts decreased compared with

control yoghurts. The maximum protein content was recorded in

the yoghurt samples with papaya juice and gelatine. Papaya was

rich in protein and these papaya fibres increased protein contents

in yogurt in high ratio (Table 2).

The ash content of the control (yoghurt without papaya juice)

was lower than that of the papaya supplemented yoghurt (Table 3).

The ash content is the amount of non-combustible matter and total

minerals present in a food. Therefore, addition of the papaya juice

to the milk had increased the ash and thus the mineral contents of

the papaya - yoghurt than in the control (Table 3).

The variation in the proximate composition of yoghurt samples

was due to the compositional difference between papaya juice

and the base milk used (Table 1 and 2). Generally, the addition

of papaya juice had a concentration effect on the composition

of yoghurt, and this was due to higher total solid (TS) content of

papaya juice as compared to milk. According to the draft COMESA/

East African standard, yoghurt should have a minimum total solidnot-

fat content of 8.2% (w/w). Codex stated yoghurt should have

a minimum of 2.7% protein and a fat content of less than 15%.

Similarly, in this study, all yoghurt samples satisfied the above

requirements (Table 3).

Total carotenoids, total phenolics and reducing power

The TC, TP and RP content of plain yoghurt samples observed

in this study were almost similar with findings of [17], and little

higher than the findings of [4] who reported TP content of 2.025 mg GAE/100 g in the plain yoghurt samples. This could probably

be due to differences in phenol content of milk samples used in the

experiments. The occurrence of TC, TP and consequently RP in milk

and dairy products may be consequence of several factors, e.g., the

consumption of particular fodder crops by cattle, the catabolism

of proteins by bacteria, contamination with sanitizing agents,

process- induced incorporation or their deliberate addition as

specific flavouring or functional ingredients [19].

The TC and TP content of papaya in the literature is quite

variable, which could be due to differences in cultivar [20] preharvest

management [21], post-harvest handling and storage [22],

processing method and the methods of analysis [19,23]. The TP

content of the papaya juice used in this study was higher than the

value (28mg GAE/100g) reported [29-32] and lower than the result

reported [33] which was 54mg GAE/100g of juice. The content of

carotene was within the range from 8.66mg/Kg to 78.07mg /Kg

reported [34].

In general addition of papaya juice results in increased TC, TP,

and RP of yoghurt and consequently the functional food property of

yoghurt was improved due to increased carotenoids and phenolic

contents which in turn could act as antioxidant and provitamin

A. Vitamin A malnutrition is one of the three most important

nutritional problems (i.e., iron, iodine and vitamin A) in the

developing countries [35] (Table 4).

Firmness and syneresis analysis

Significant differences (p<0.05) were found in firmness (Table

5) and syneresis (Table 6). The values for firmness were highest

for the highest level of papaya juice and gelatine and lowest for

the control yoghurt samples. The papaya yoghurt was significantly

lower syneresis and more firmness than the control. The papaya

juice had the most influence on the textural quality of the yoghurt.

This result could be due to the pectin component of the papaya juice

reinforcing gelatine, which tended to produce resistance to the

structural deformation of the yoghurt. It was speculated that the

addition of the fruit juices to the yoghurt might increase syneresis

and affect the strength of the internal bonds formed in the food. The

ability of a gel to exhibit syneresis, viscosity, rigidity and elasticity

will be affected by the types of protein, the temperature and

time of heating, the protein concentration, and the ionic strength

[36]. Several studies of milk gel interaction and its rheological

properties have previously been reported and noted that various

polysaccharides such as xanthan gum, wheat starch, gelatine

and locust bean gum can be used in yoghurt for higher shear

consistency and viscosity [37-40]. The combination of pectin and

sugar in the presence of acid contributed to the gelling properties

of milk and subsequently affected its texture [41]. An appropriate

thermal process was applied during the sample preparation to

denature the enzymes papain found in papaya juice to avoid the

hydrolytic digestion of milk protein. Proteolytic enzymes would

have interfered with the interaction between milk casein and whey

protein to form the milk-clotting structure [42].

Sensory analysis

Table 5 shows the sensory analysis of the yoghurt samples.

Addition of papaya juice significantly (p<0.5) affected the score of

yoghurt samples by the consumer panelists for appearance, color,

body and texture and overall acceptability (Table 5). Panelists’

rating for appearance and color was similar for all yoghurt samples

but yoghurt with 10% papaya juice was rated significantly (p<0.5)

higher than the (control) without papaya juice (Table 6). Addition

of up to 15% papaya juice received significantly higher mean score

for overall acceptability, which was in the range of 6.20 to 7.55 (i.e.,

in the range between like and like very much). However, addition of

20% papaya juice decreased the ratings to 4.45 to 5.30, which was

between dislike slightly and like slightly.

Yoghurt samples with 10% papaya juice received higher mean

scores for overall acceptance than yoghurt samples with other

all papaya juice levels but the difference in mean scores between

yoghurt sample without papaya juice (control) was not significant

(Table 7). For all sensory attributes, yoghurt samples with 10%

papaya juice had significantly higher mean hedonic scores than the

control (without papaya juice), except for appearance in which case

both samples received similar scores (Table 7).

Most of the scores given by consumers for appearance,

texture, flavor and overall acceptability for each treatment, were

concentrated between 5.50 (like slightly) and 7.50 (like very much),

on the liked part of the scale for all the treatments.

However, despite the unfamiliarity of the consumers to papaya

supplemented yoghurt, participants found the sensory attributes

of yoghurt supplemented with papaya juice to be very acceptable.

This could be explained by the familiarity of consumers for the

individual ingredients, i.e., papaya and milk [43]. In this study,

yoghurt containing 10% papaya juice at all gelatin level had overall

acceptability compared to all the other treatments (Table 7).

Conclusion

Functional and nutritional values of yogurt and fermented dairy

products can be enhanced by adding papaya fruit. In this study, the

physicochemical and the majority of the characteristics of yogurts

remained unaffected. This value-added functional yogurt appeals

to a wide variety of consumers; therefore, it may have the potential

to increase sales in the yogurt market. Generally, the results of the

current study indicated the possibility of producing papaya juice

supplemented yoghurt commercially under small or large-scale

condition.

Please follow the URL to access more information about this article

https://irispublishers.com/gjnfs/fulltext/effect-of-papaya-juice-and-gelatine-on-the-physicochemical-and-acceptability-of-yoghurt.ID.000514.php