Authored by Stephen Agyeman*,

Abstract

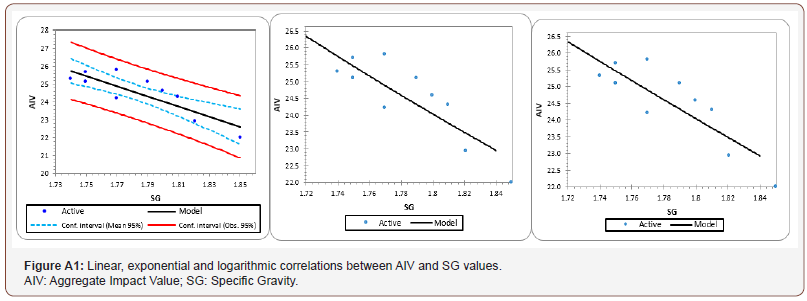

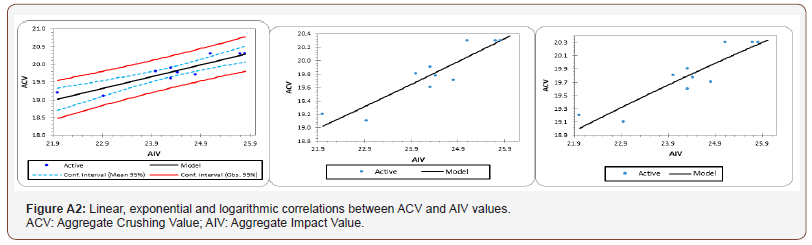

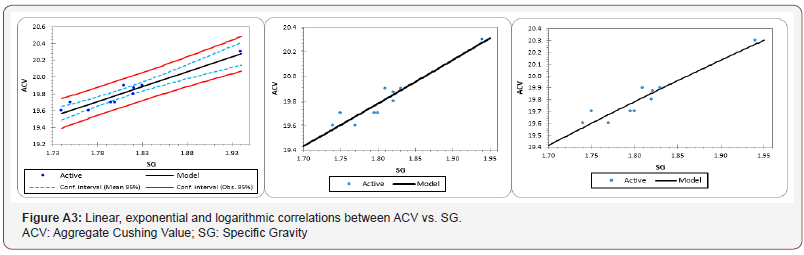

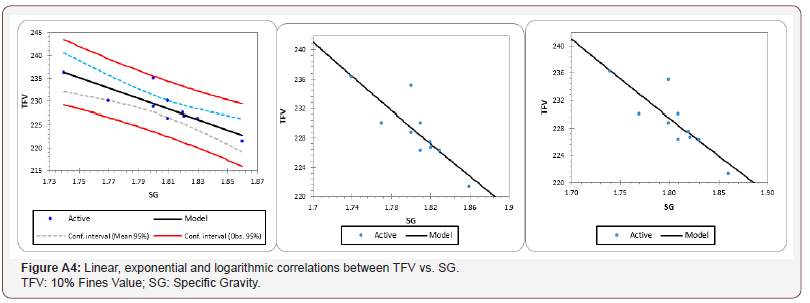

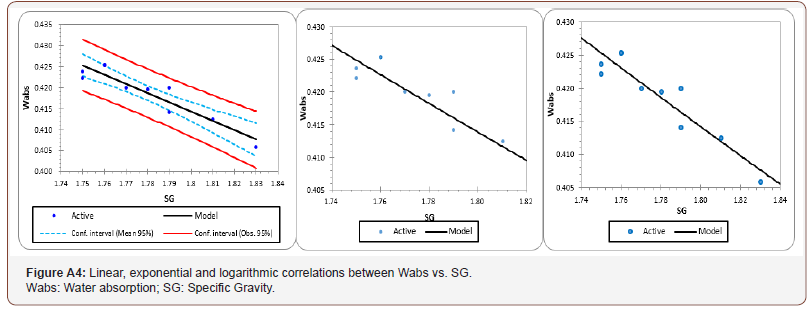

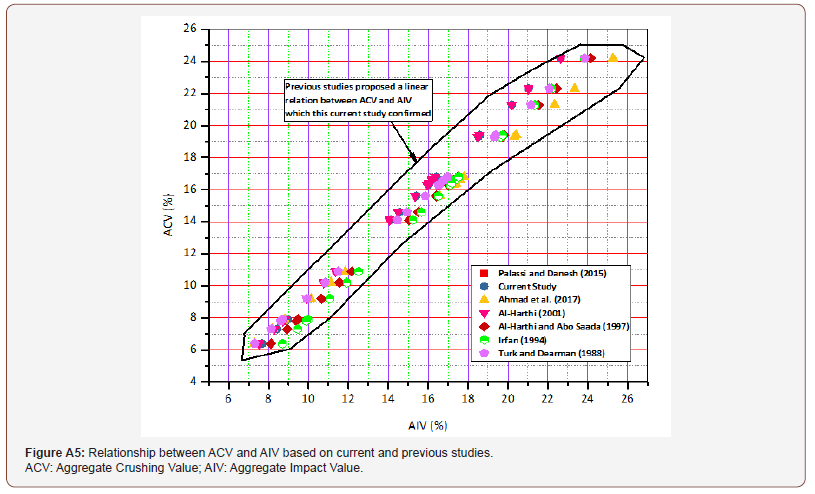

Granite and its derivatives are the dominant rock source of most quarry products (rock aggregates) in Ghana. However, they may differ in term of quality, the mineralogic composition and so forth in their geospatial locations. This could be due to the variation by alteration process, weathering and deformation. This also suggests that different location of quarries may produce different quality and properties of quarry products. Rock aggregate plays an important role depending on its intended use. It is therefore essential to understand the properties and qualities of the rock products to achieve required dimensional stability, durability and strength of structures using rock aggregates characteristic and related engineering properties tests. The study evaluated physical and mechanical properties of rock aggregates from Quarries A and B. Samples of rock products from these quarries were subjected to a battery of laboratory tests to determine their physical, mechanical and geometrical properties. The rock aggregates from Quarries A and B met all the physicomechanical requirements for use as aggregates for crushed rock subbase, base and surface dressing for pavements. Correlations were established with R2 of 0.833 amongst ACV and AIV, R2 of 0.732 between AIV and SG, R2 of 0.905 amongst ACV and SG, and R2 of 0.718 between TFV and SG and of 0.872 between Wabs and SG. The best regression equations were shown to be logarithmic and exponential. The recommendation is to adjust processing and the degree of crushing at the two-plant sites to produce appropriate, particle size for the various pavement applications.

Keywords: Physicomechanical properties; Pavement application; Rock aggregates; MRT specifications; Granite; Ghana

Introduction

Construction aggregate fundamentally is a raw material in all countries with the largest growth observed in industrial and construction materials [1-6]. The demand and appetence for this material will continue to be highest in the developing countries that are eager to close up the infrastructural gap with the developed countries [3,7-9]. Close to 20 million cubic meters of crushed rock aggregates are consumed per annum in Ghana [10,11]. The road construction sector alone takes roughly 70-80% of the total aggregate produced in the country as opposed to 448,000 cubic meters every year as opined by Kuma [12]. The dominant rock outcrops used for the production of construction materials and aggregates in Ghana is granite and its derivatives [12-16]. However, it may differ in term of quality, the mineralogic composition and so forth throughout different source locations [5,11]. This could be attributable to the variation by alteration process, weathering and deformation. Mohtarami and others [17] have also observed that chemical processes cause a change in the mineralogy, chemical composition, porosity, and permeability of rocks. Buertey et al. [2] and van de Wall and Ajalu [18] suggested that different location of quarries may produce different quality and properties of quarry products which can affect the physicomechanical properties as well as the final product. Thus, van de Wall and Ajalu [18] asserted that the quality of rock aggregate rests on the lithological variations existing in the rock deposit. The battery of laboratory tests and material specification are thus indispensable when rock aggregates are to be used in construction.

However, the testing and specification of crushed rock aggregates are often overlooked or not considered in most civil engineering construction across many jurisdictions in the world [5,19]. This often has serious implications for the life and maintenance of buildings and road infrastructure. This usually costs a lot of money in the future to repair or replace and at worst lead to structural failure and risk to human lives [20,21]. Most roads are failing prematurely owing to the properties of rock products either falling below the standards or as a result of poor construction methods and quality control [22]. Additionally, most carnages due to road traffic accidents on Ghanaian roads can be attributed partially to too little friction resulting from poor aggregates characteristics.

To contribute to addressing the foregoing challenge, tests were done to investigate the physicomechanical properties of quarry products (rock aggregates) from two quarries in the Bono Region, Ghana used for structural pavement layers. In addition, analyses were completed to find out the effect of the aggregate properties on pavement performance.

The aim of this study was to investigate whether physicomechanical properties of quarry products produced in Bono Region meet specifications. The specific objectives were:

1. To analyses the physicomechanical and geometrical properties of quarry products.

2. To compare the physical and mechanical properties of quarry products with Ghana’s Ministry of Road and Transportation (MRT) Standard Specifications.

3. To assess the suitability of these quarry products as pavement materials for base, subbase and aggregate for surfacing.

The results of the study have given impetus to consultants to confidently recommend quarries aggregates that meet specifications for road pavement construction. Furthermore, contractors can now source constructional materials from these quarries whose products meet the MRT specification in the Bono Region of Ghana. Using the published laboratory test results, quarries whose products fail to meet MRT requirements can make amends.

Background of the two quarries

Quarry 1 designated as A is located at the right-hand side along the Sunyani-Wenchi road known as Beposu which is about 45.5km away from Sunyani. The rocks found at the site include Granite, Gabbro and Metamorphic rocks [15]. The quarry produces aggregate sizes of 10mm, 14mm, 19mm, 20mm, 30mm etc./

Quarry 2 also labelled as B is located in the same area but on the left-hand side of the road from Sunyani-Wenchi, of about 47km from Sunyani. It has the biggest known quarry plant in the country (Ghana) currently. The quarry has an area of about 26 acres of land and Granite, Basalt, Gabbro and Slate as its rocks [15]. The quarry produces aggregate sizes of 0-5mm known as quarry dust or quarry fines, 10mm, 14mm, 19mm, 25mm up to 40mm, but only produces 50mm on customer demand. The company produces about 50t of aggregates per hour.

Both quarries were established in the years 2000 and 2007 respectively with the mandate of delivering quality products for the construction industry. The said quarries were committed to total customer satisfaction as they strived continuously to improve upon their operations. Besides, the provision of construction materials for the Bui Dam Hydroelectricity Project in the region, the quarries have expanded their operations to include other civil construction projects. With the capacity to produce over 360,000 mt of aggregates per year for quarry A and 400,000 mt of aggregates per year for quarry B. Efforts are constantly being made to increase their capacities to meet the quarry needs of Ghana’s vibrant and rapidly expanding construction industry [10,11,23].

Materials and Methods

The methodology used involves field sampling and laboratory testing. The laboratory tests have been described under two captions, namely; physical and mechanical properties, and geometrical properties. The laboratory tests were carried out in accordance with the relevant British Standards Institute (BSI) standards and European Standard (CEN), which in most cases are equivalent to the corresponding American Society for Testing and Materials (ASTM) standards [24].

Field sampling

Sampling was carried out in accordance with the European Standard procedures EN 932-1 [25] which require, among other things, that when sampling from a heap of aggregates, a number of increments are to be taken from positions evenly distributed over the whole surface of the heap. In this study, for each of the two deposits (at quarries named A and B), five to seven positions, evenly distributed over the surface of the heap were selected. Then at each sampling location, the top 0.1m of the material was removed to expose the aggregates. Subsequently, about 350 kg of material was incrementally dug to a depth of 0.3m using shovels and scoopers and bagged. The samples were then split up into bags for easy handling and transportation to the lab for the various lab tests.

Laboratory testing

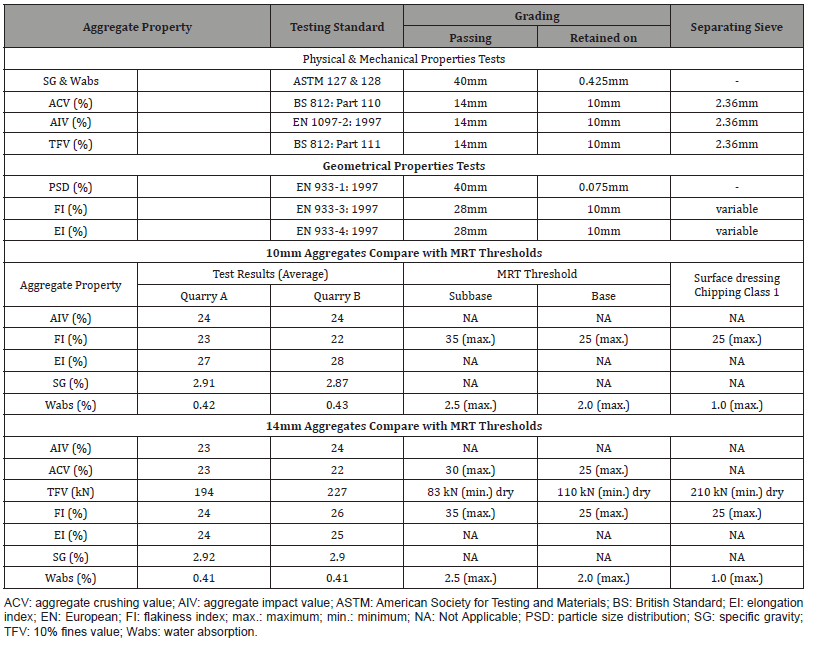

The bulk samples from the field were separated into smaller portions by riffling, using the European Standard processes EN 932-2 [26]. Testing was done using BSI and ASTM standards (Table 1).

Table 1: Testing standards, properties of 10mm and 14mm aggregate compare with MRT [42] thresholds.

All the tests were repeated ten times and their average values found. The riffled specimens were washed through the 0.075mm British Standard (BS) sieve to free all fines and then dried for 24 hours at a temperature of 1050C before testing. The specific gravity (SG) and water absorption (Wabs) tests were done using ASTM C127 and ASTM C128 respectively.

Also, geometrical properties tests were done using EN 933-1 [27] for particle size distribution (PSD), EN 933-3 [28] for flakiness index (FI) and EN 933-4 [29] for elongation index (EI). The aggregate crushing value (ACV) and ten percent fines value (TFV) tests were also done using BS 812: Part 110 [30] and BS 812: Part 111 [31] correspondingly. Lastly, EN 1097-2 [32] was used for the aggregate impact value (AIV) test.

Results and Discussion

Geology of study area

The geology of the quarries A and B are made up of rocks have medium to fine coarse-grained texture and greyish in color. The prominent outcrops in the study areas comprise Southern Voltain rock formations of granite minerals of mica, feldspars belts with thin veins of biotite’s, garnet gneiss. The principal soil type is a blend saprolites of Bekwai and Akumadan soils series [15,35]. These rocks are mostly folded, fractured and have a general southwest strike with low dips. The felsic minerals (mostly quartz and feldspars) and the mafic minerals (mostly biotite and hornblende) form bands within the rock. The quartzite veins are either oriented parallel or oblique to the foliation. They have a complex structure with patches of amphibolite phase and intrusions of pegmatite and quartz veins. These geomaterials are highly jointed. There are many joint sets, prominent among the join sets are south-east to south-west with the irregular spacing characteristic of these rock formations in the area [15,35-41].

Evaluating the quarry products for road pavement applications

Laboratory testing standards well as the properties of 10mm and 14mm aggregates compare with MRT [42] thresholds are shown in Table 1. The mechanical properties comprise abrasion resistance, elastic modulus, polish resistance, and strength while the physical properties are absorption, gradation, properties of micro fines, shape, angularity and texture, and thermal expansion [19]. The physical properties such as mineral content and the microstructures of the intact rock influence various rock characteristics [36] and are important in every sphere of application [37]. The physicomechanical properties that were considered in the study include abrasion resistance, strength, absorption, gradation and shape.

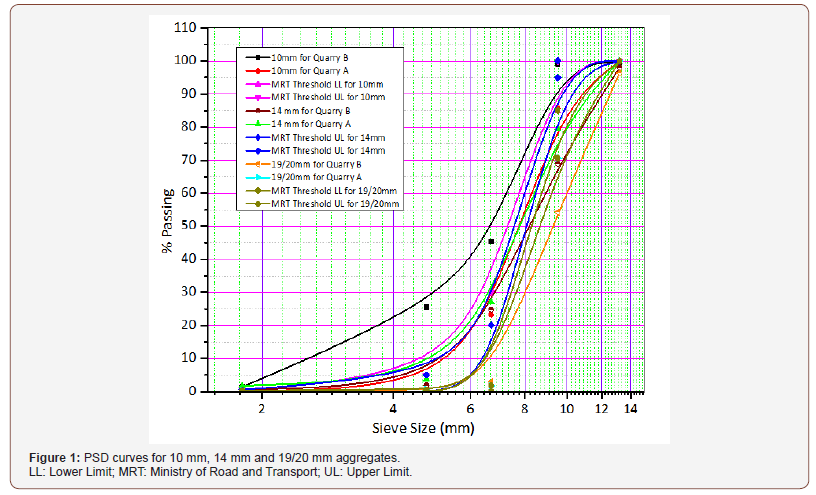

Particle size distribution: The extent by which an unbound aggregate material is deformed when loaded depends on its stiffness, stability and load-bearing capacity. These three properties and among others are, dependent on the compaction result, which is in turn dependent on the PSD and the particle shape [38]. Different aggregate sizes give different strength values and abrasion according to Su and Cheng [39] and Okonta [40]. The linear diminution of rock strength with an increase in grain size has been reported by Onodera and Asoka-Kumara [41]. Figure 1 shows the grading curves for chipping sizes 10mm, 14mm, 19mm.

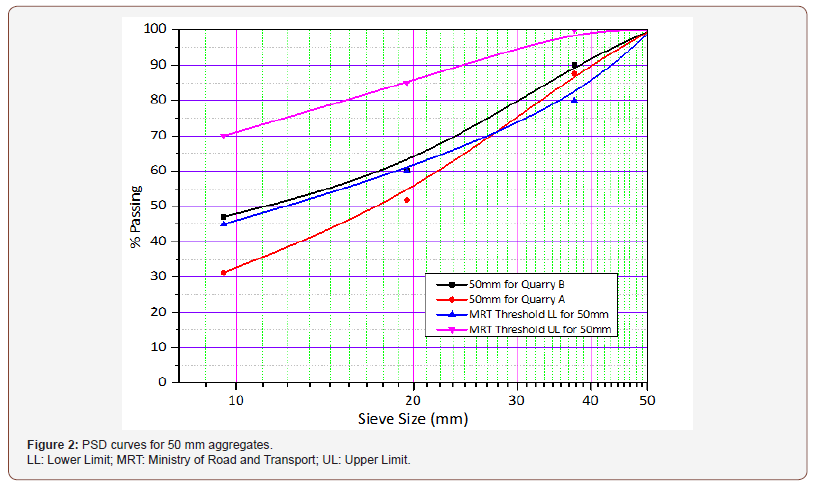

For the 14mm and 19/20mm chipping sizes, the grading curves in Figure 1 fell outside the MRT [42] envelop. This indicates that further processing (crushing and screening) will be required before they can be used in the pavement layer. Correspondingly, the PSD curves of the 0/50mm aggregate all fall outside the grading specification and will require further processing to require particles sizes for usage. Figure 2 shows the grading curves for 0/50mm crushed rock aggregates.

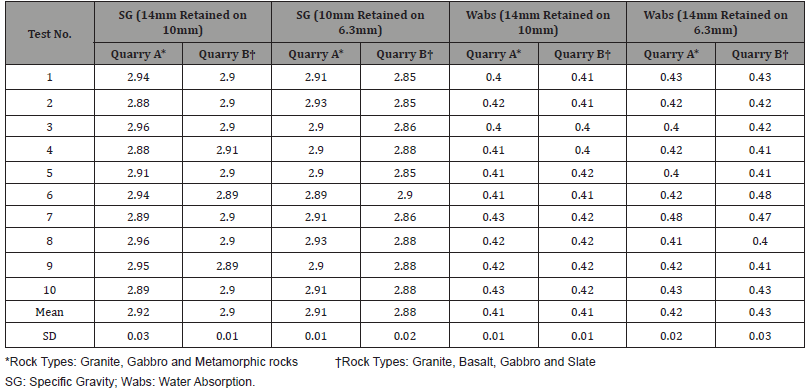

SGs and water absorption.

The key test used in evaluating the permeation property of the aggregates was water absorption (Wabs). Literature by Rigopoulos and others [43], and Scholer [44] have it that, rocks with values greater than 3% are prone to freeze-thaw damage. The specific gravities (SGs) and Wabs results as shown in Table 1 are within the spec limits.

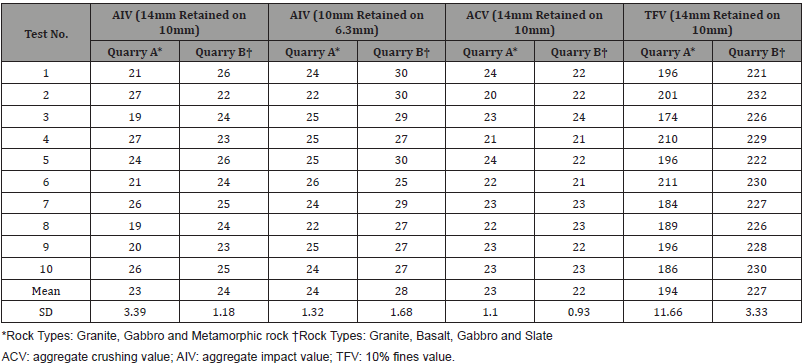

Aggregate strength: Asserted by Arm [38], the resistance to mechanical action depends on the particle strength, which also depends on the geometrical shape, the mineral composition and cohesion and the structure as well as texture of the particle. The ACV measures the percentage of fines generated when a uniformly increasing force attains a maximum value of 400 kN in 10 minutes [24]. The results in Table 1 indicate that the 14mm chippings from Quarries A and B have mean ACV value of 20%, which is less than the maximum specified limits of 25% and 30%, respectively required for crushed rock base and subbase aggregate. Aggregates with TFV less than 8 kN are considered too weak for use in road pavements [45]. Therefore, the TFV of 229 and 227 kN dry are within the required specifications as applied in subbase (83 kN), base (110 kN) and surface dressing chippings class 1 (210 kN) [42] and can, therefore, withstand degradation [22].

The AIV test provides a relative measure of the resistance of an aggregate to sudden shock, granulation or pulverization as might occur under a vibratory roller and traffic loading [22,24,43]. The MRT [42] does not use AIV to assess aggregates, but aggregates with AIV exceeding 25% are normally regarded as being too weak and brittle to use in a pavement [45,46]. The mean AIV value shown in Table 1 again indicates a very tough material that can be used in road pavement layer applications.

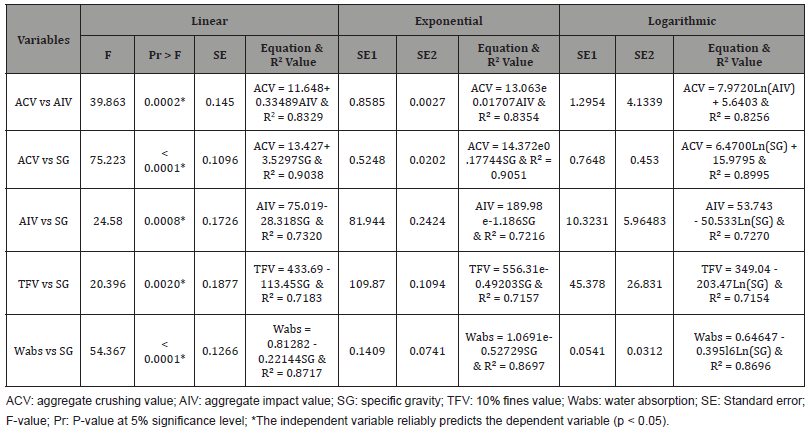

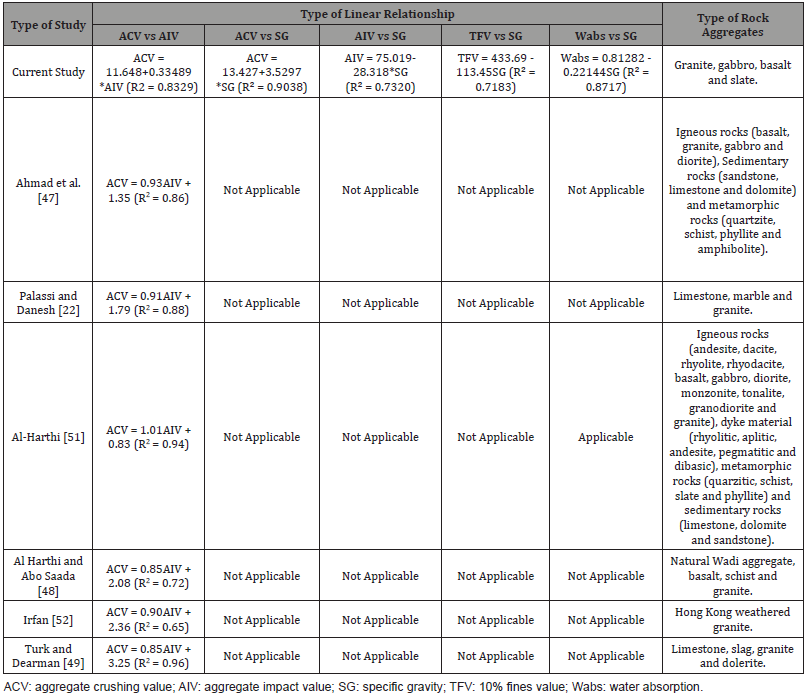

Linear relations were found between ACV and AIV as well as SG and ACV, AIV, TFV or Wabs when the data was fitted using regression equations (linear, logarithmic and exponential). For instance, the correlation found between ACV and AIV in Table 2, shows that approximately 83.3% of variations in the data are explained by the linear model. The results are in tandem with those obtained by Ahmad and others [47], Palassi & Danesh [22], Al Harthi and Abo Saada [48] and Turk and Dearman [49] who worked on granites and other rocks (see Figure A5). The marginal deviation between the current study and the previous studies correlation results may be attributed to the differences in the type of rock aggregates worked on by the individual researchers. However, there is a strong agreement between this study’s results and those by Al Harthi and Abo Saada [48] who worked on similar rocks as granite, gabbro, basalt etc. All the P-values were significant at 95% confidence interval (p < 0.05). This indicates that all the independent variables (SG & AIV) reliably predict the dependent variables (ACV, TFV, Wabs and so on).

Table 2: Correlation between TFV, AIV, SG and ACV using different forms of regression.

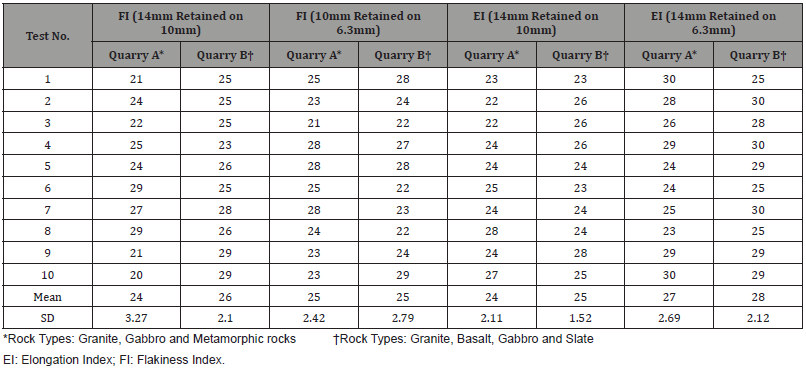

Geometrical properties of quarry aggregates: The shape of an aggregate determines its interlocking performance potential although such aggregates have less workable breaking characteristics in loading and workability [49,50]. Usually, angular aggregates are recommended for highway construction because of their better interlocking characteristics [24]. The mean values of the flakiness indices of 23% and 22% for the 10 mm and 24% and 26% for the 14 mm (Quarries A and B) are less than the MRT threshold of 35%, 25% and 25% specified for subbases, base and surface dressing correspondingly. Details of the lab test results are presented in the Appendix as Tables A1 to A4 and Figures A1 to A5.

Table A1:Correlation between TFV, AIV, SG and ACV based on current and previous studies.

Table A2: Test results of FI and EI for quarry A and B aggregates.

Table A3:Test results of AIV, ACV and TFV for quarry A and B aggregates.

Table A4: Test results of SG and Wabs for quarry A and B aggregates.

Conclusion

Samples of quarry aggregates derivative from the Southern Voltain rock formations of granite minerals of mica, feldspar belts with thin veins of biotites and garnet gneiss were collected from two quarries and subjected to a battery of laboratory tests. The following specific conclusions can be deduced from the results:

• The quarry products have fairly uniform mechanical and geometrical properties.

• The high resistance against crushing, as indicated by the low mean ACVs of 20% and high TFV of 277 kN, compared with the MRT specified maximum ACV of 30% and 25% for subbase and base respectively, and minimum TFV values of 83 kN, 110 kN and 210 kN respectively, for subbase, base and surface dressing. The aggregates are suitable for pavement layers’ applications.

• The tested properties were linearly related. For example, correlations were established with R2 of 0.833 amongst ACV and AIV, R2 of 0.732 between AIV and SG, R2 of 0.905 amongst ACV and SG, and R2 of 0.718 between TFV and SG and of 0.872 between Wabs and SG. The finest regression equations were found to be logarithmic and exponential.

• The results suggest that the aggregates have a relatively low affinity for water as indicated by the relatively low Wabs averages of 0.42% and 0.41% for Quarries A and B respectively compared with a threshold of a range of 1.0 to 2.5% for base, subbase and chippings class 1 for surface dressing. The quarry products can be used as road base, subbase and surface dressing material.

• The overall conclusion is that the quarry products from the Quarries A and B met all the physicomechanical requirements for use as aggregates for crushed rock subbase, base and surface dressing for pavements. What is required is to adjust processing (screening) and the degree of crushing at the two processing sites to produce appropriate particle size for the various pavement applications.

To read more about this article...Open access Journal of of Engineering Sciences

Please follow the URL to access more information about this article

To know more about our Journals...Iris Publishers

To know about Open Access Publishers

No comments:

Post a Comment