Authored by AK Chandel*,

Abstract

Automation in agriculture is gathering a prominent base for enhanced mechanized farming. These technologies save excess labor, effort, time and costs involved in pertinent methods of crop production. Furthermore, avoiding drudgery and health risks. Weed management especially in the intra-row zone is one of the most tedious operations, involving excess costs and health risks when performed manually. In this regard, an intra-row sensor based weeding technology was developed that removes weeds in the intra-row zone in addition to protecting the main crop by sensing their physiology. A controller algorithm was developed to direct the electro-mechanical units for efficient operation. The system was tested for its sensing accuracy and encountered plant damage while preliminary evaluations. The overall operating efficiency varied within 80 to 96 % when evaluated under different plant spacing.

Keywords: Automation; Intra-row weeding; Sensor; Lateral shifting mechanism; Microcontroller

Introduction

Timed and efficient agricultural practices are required for enhanced crop production. One of such practices is appropriate and timely management of weeds that affect crop yield over 33 % by competing for nutrients and other resources supplied for optimum crop growth [1]. Several methods for controlling weeds have been explored such as manual, chemical, biological, mechanical and mechatronic [2-4]. However, these methods are only targeted for weed control in the inter-row zone while the intra-row weeds remain unharmed. Manual method of weed control is the earliest and smoothest of all but induces severe consequences of health risks due to excess fatigue and bending along with skin infections [5]. Chemical application is another method that is being explored. However, the presence of herbicide resistant weeds and increasing demand for chemical free food has initiated investigation of alternative methods [6]. Intra-row weeding is also challenging due to weeds aligned with main crops. Pertinent to these circumstances, an ultrasonic sensor-based precision weeding system was developed. This system integrates sensor with lateral shifting mechanism (LSM) through a microcontroller algorithm. This study therefore summarizes the development of this technology along with its preliminary evaluation towards sensing accuracy and plant damage.

Methods and Materials

The intra-row weeding setup

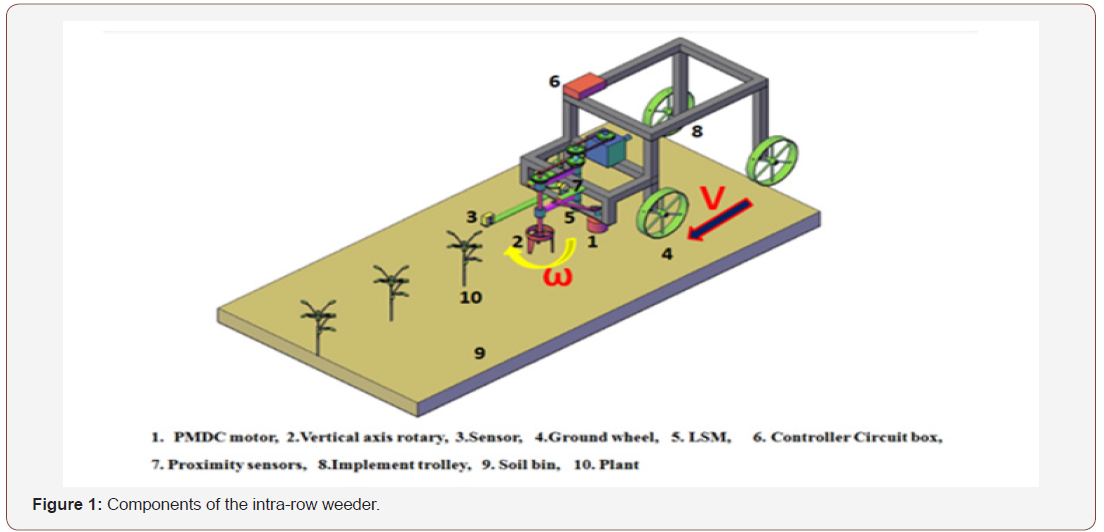

A vertical axis rotary mounting weeding blades (Figure 1) around its periphery was developed as the weeding tool that was operated with lateral shifting mechanism (LSM). The movement of LSM was governed by the real time sensing of crop height by an ultrasonic sensor and a single board computer (ATMEGA 328).

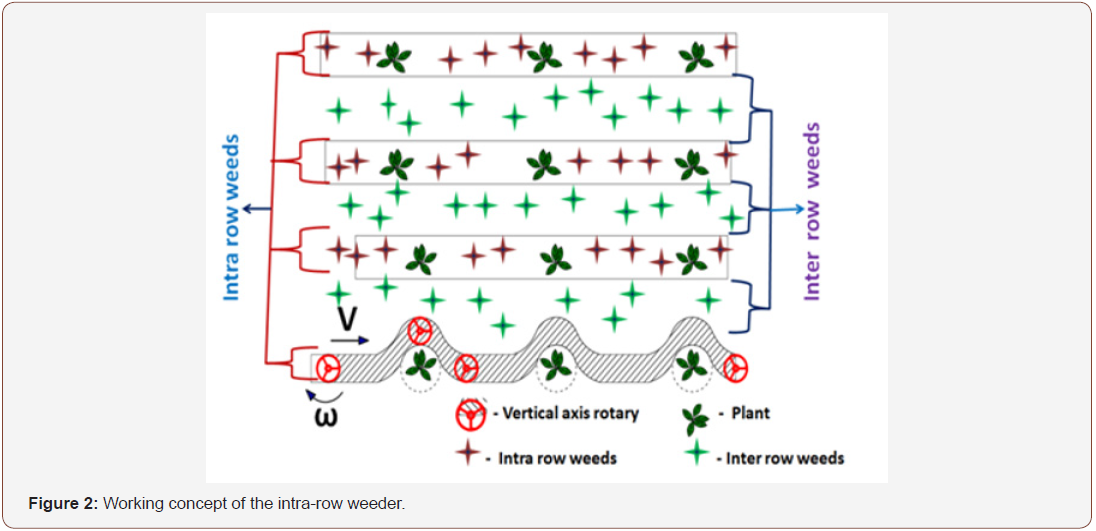

The electronic sensing and control unit consists of an ultrasonic sensor, microprocessor, proximity sensors, direct current motor (0.5 hp) and motor controller. The ultrasonic sensor was placed on a telescopic rod at 30 cm ahead of the vertical rotary based on the operation delay of the electronic control unit. Initially, the vertical rotary rotates around its own axis in the intra-row zone and is traversed forward by a prime mover. During the forward course, as the main plant is identified by the sensor, the controller actuates the motor to laterally shift the rotary weeder out of the travel line, this avoids the damaging the main plant. The original position is retained as the plant passes by and weeding continues. The working concept of the weeding system is shown in Figure 2. Two proximity sensors were installed in the system to limit the lateral movement of the vertical rotary within the plant protection zone. to control the rotary position in weeding and plant protection zone according to sensors signal. A CAD view of soil bin setup of intra row weeding system is shown in Figure 2.

Evaluation of intra row weeding technology

The developed setup of the intra-row weeder was evaluated in the soil bin laboratory of the Agricultural and Food Engineering Department, IIT, Kharagpur, India. A soil processing trolley was used to prepare test bed under different soil conditions (compaction, moisture etc.). The developed setup was driven by the implement trolley. Artificial plants were planted in the soil bed at different spacings and system was driven at different speeds to determine the sensing accuracy and damage that later estimated the overall operating efficiency.

Results and Discussions

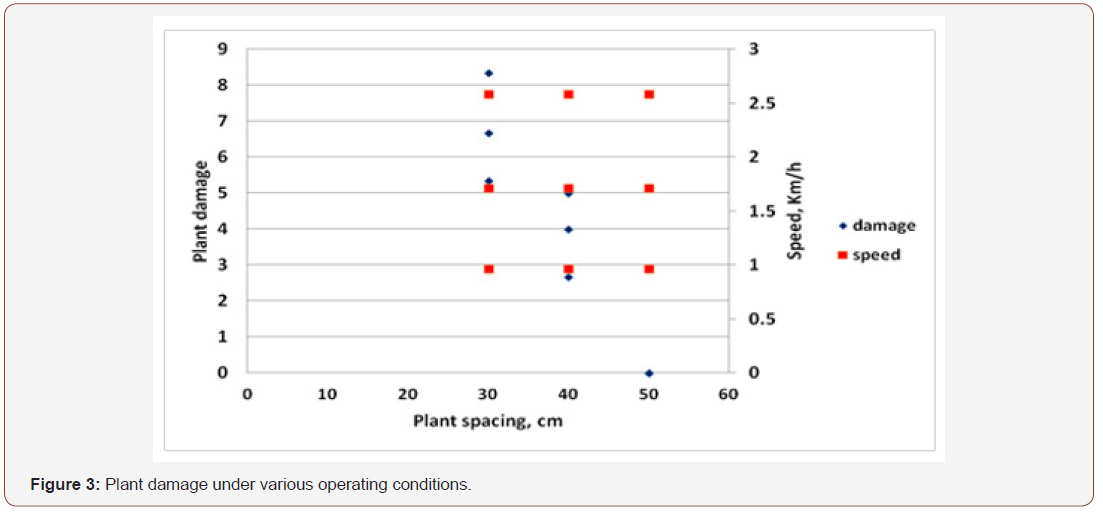

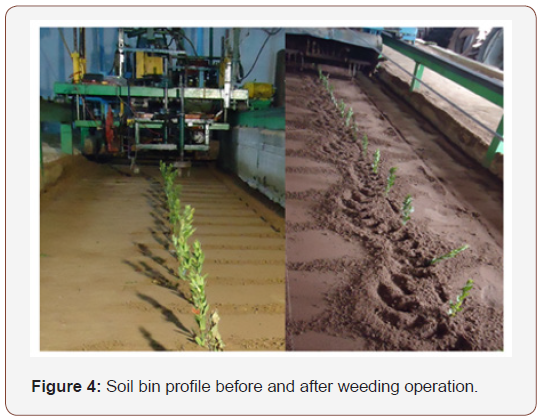

The operating accuracy (Figure 3) of 96.30% was obtained under plant spacing of 50cm, forward speed of 1.92 km/h, motor speed of 150 RPM and operating delay of 70 ms. Similarly, a maximum operating accuracy of 80-85% was obtained for plant spacing of 30 and 40cm at a forward speed of 2.45 km/h, motor speed of 200 RPM and operating delay of 0 ms. The soil bin profile before and after the intra-row weeding is shown in Figure 4.

Conclusion

An intra-row weeder prototype was developed in integration with the electronic control system for removing weeds and avoiding interference with the plants at same time. A fine amount of operating accuracy can be obtained with such systems by identifying the suitable operating conditions. The systems also guarantee minimal negative effects on environment and main crops.

To read more about this article...Open access Journal of of Agriculture and Soil Science

Please follow the URL to access more information about this article

To know more about our Journals...Iris Publishers

To read more about this article...Open access Journal of of Agriculture and Soil Science

Please follow the URL to access more information about this article

To know about Open Access Publishers

No comments:

Post a Comment