Authored by Dr Sana Ullah Balouch1*,

Abstract

In this paper reinforced concrete beam column joint is modelled and analyzed using ABAQUS software to compare the simulated results with the experimental study. The joint is the most critical and most important part of the multi-story frames or multi-story buildings when they are subjected to earthquake loading. In this research the joint is analyzed for two different types of non-linear analysis that is non-linear static analysis and a part of non-linear dynamic analysis for the visual comparison with the experimental study.

Keywords: Beam column joint; Steel fibers; Earthquake; Cracks; Finite element analysis; Abaqus

Introduction

The use of fibrous reinforced concrete was firstly seen at an immense level in pavement and sprayed concrete, and it is enlarging itself to number of other fields and areas of construction. Reinforced concrete with the steel fibers in it has a very potential application in the multistory frames or high-rise buildings when they are subjected to earthquake that is to the repeated cyclic loading and also reinforced concrete with steel fibers does not require many efforts in construction techniques. To explore such potential, the existing body of knowledge on SFRC must be expanded to cover for enhancing the flexural strength of concrete. A lot of research has been done improving the concrete strength [1]. Beam column joint, being the most important part of the civil engineering structures are considered as most critical under earthquake condition for elastic and plastic behavior. Normally, the beam column joints in frames and multistory buildings are generally not designed for seismic earthquake loading. It is very important to consider the bond slip of longitudinal bars and joint shear deformation in finite element analysis and neglecting these effects in modelling will lead to the misleading results. When the beam column joint is subjected to the cyclic earthquake loading a high concentrated shear stresses are generated. Shear strength and bond slip degradation could possibly occur in the joint after the beam is yielded. The failure in joint usually occur due to two main reasons;

1. Bond failure of longitudinal reinforcement.

2. Shear failure at the joint core area.

These are not desirable because they can lead to the immediate failure of the joint due to repeated vibration during earthquakes and can cause significant damage, collapse, or excessive drift of the structure. Therefore, steel fibers are used in the beam column joint to the strengthen the joint against shear and bond failure. Steel fiber reinforced concrete has a potential application in building frames due to its high seismic energy absorption capability and relatively simple construction technique. Beam Column joints are an important part of every frame structure or multistory structures and the joints behavior against the earthquake condition play a significant and important role [2-4]. Lack of shear reinforcement in the joint is the main reason for catastrophic collapse and failure when the beam column joint is subjected to the earthquake conditions [5,6]. An experimental work is necessarily carried out for finding the parameters which affect joint performance and to determine the critical part of the joint, so to enhance the properties and performance of the joint [7]. In the past two to three decades numbers of publications are given in worldwide that gives in detail the design of reinforced concrete beam column joint and recommendations for the improving the performance of the join and also numerous studies are carried out on modelling of these joints.

According to the ACI suggestion of reinforced concrete beam & column joint specifications, Beam-column joints are crucial locations in building for the reinforced concrete framed structures, may be unstable, in earth quick exposed (prone) regions. Appropriate anchorage of reinforcement is essential to improve the actual functionality [1]. Progressive joint structural designs that can decrease congestion of reinforcement steel without compromising on strength and capability, stability and stiffness are suitable. Behavior of beam-column joint of M20 concrete, when subjected to seismic loading with the use of 1.5% steel fibers. For this the specimen was tested under cyclic and reverse cyclic loading. The parameters analyzed for the samples were ductility, energy dissipation, load v/s displacement curve, beam-column reinforcement strain and crack pattern. For these 6 samples were prepared with IDs O1, O2, S1 and S2 were samples 9 with no steel fibers and F1 and F2 were the samples with 15% steel fiber. The main reinforcement for these samples was 8mm and shear reinforcement was 3.3mm. It was observed that the beam-column joint with 1.5% steel fibers performed 10% more effectively in all the tests. So, it is more effective against the earthquake [8]. A beam column joint of RC frames was analyzed for the earthquake response. Simulations of the inelastic response of typical beam-column joints in two-dimensional nonlinear analysis of reinforced concrete frames is done by this model. Constitutive models are made to define the response of the shear-panel and barslip components of the model; the results are computed on the basis of concrete and steel material properties, the beam-column joint geometry and the distribution of reinforcing steel design. Comparison of simulated and observed results for a series of beam-column joint building sub-assemblages indicates that the prepared model represents well the fundamental characteristics of response for joints subjected to moderate shear demands [9].

Preliminaries and Objectives

Objectives

The main purpose of this research is to model a beam and column joint with steel fibers when subjected to earthquake loading and study the non-linear behavior of the joint. Following are the main objectives of this research.

a. To use suitable methods and tools to model a RCC beam-column joint with fibers in CAE software.

b. To do the non-linear analysis of modelled beam-column joint.

c. To compare the simulated results with the experimental study conducted in [1].

d. To come up with some recommendation based on the simulated beam-column joint and comparison of simulated results with the experimental study.

e. To provide guidelines for the future research.

Preliminaries

A modelling may represent a real phenomenon, but it is never possible to model the exact real phenomena. In short, number of assumptions are taken into account to make a model that represents a real phenomenon. Following are the assumptions used in this research.

a. As there are no empirical relations for modeling of tensile behavior of fibrous concrete so empirical relations for pure concrete are used to model the fibrous concrete as well.

b. As contract properties and parameters like friction co-efficient, shear and stiffness are not available from experimental study, so a tie constrain in ABAQUS is used to make the monolithic and homogenous connection between different parts of the model.

c. A perfect bond between steel reinforcement and concrete is considered that is no slippage is taken into account.

d. Also, a bilinear behavior of steel is considered.

Methodology

Overview

Modelling of steel fiber reinforced concrete beam column is the done with the help of computer software Abaqus, which is used worldwide for finite element analysis. Compressive strength of concrete (which was used in experimental work) was used to determine different parameters with the help of constitutive law of S. Majewski model and Eurocode 2, whereas SFRC was modelled using empirical relations given by A. Samer Ezeldin,1 Associate Member, ASCE, and Perumalsamy N. Balaguru. Compressive and tensile behavior for concrete was model in concrete damage plasticity (CDP) model while a high strength reinforcement was used in the experimental which was model for perfect elastic behavior. Therefore, after obtaining all the parameters and properties a T-joint was modelled with the help of built-in modules in Abaqus whose analysis was carried out for cyclic earthquake loading.

Experimental Study

Dr. Sana Ullah Balouch (2009), conducted experimental work on reinforced beam column joint with steel fibers and without steel fibers, analyzed and compared the result for both. In this research paper, the simulated data from ABAQUS will compared only with the steel fibrous reinforced concrete beam column joint.

Joint design

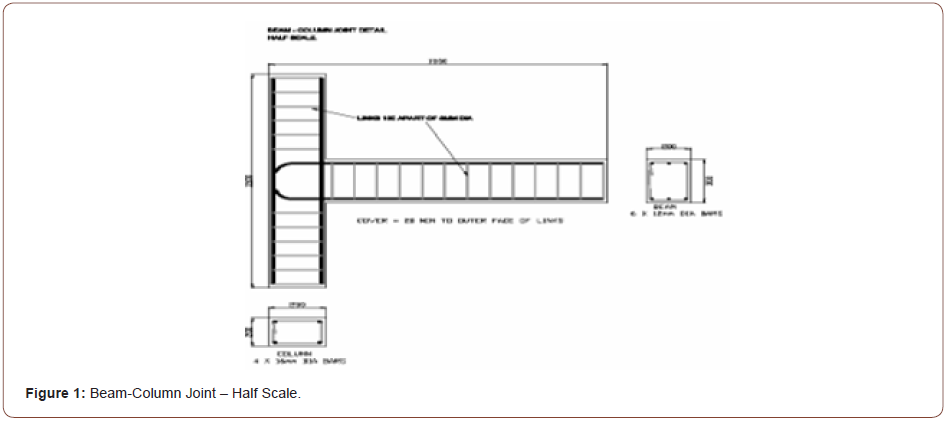

A half-scaled joint was designed with column cross section of 250mm x 200mm and beam cross section of 300mm and 200 mm wide. Beam top and bottom longitudinal reinforcement was 3 bars of 12mm diameter (3.39-cm2) or 3 #4 (0.60-in2). Column longitudinal reinforcement was 4 bars 16mm diameter (8.06 cm2) or 4 #6 – 5/8 (1.23 in2). Ties/hoops were 8mm or #3 at 100mm centers both for column and beam. These values are approximately equal to half of the reinforcement for the full-scale joint. The steel areas were rounded to achieve the reasonable re-bar size. The bar arrangement for a plain concrete specimen (Figure 1) [1].

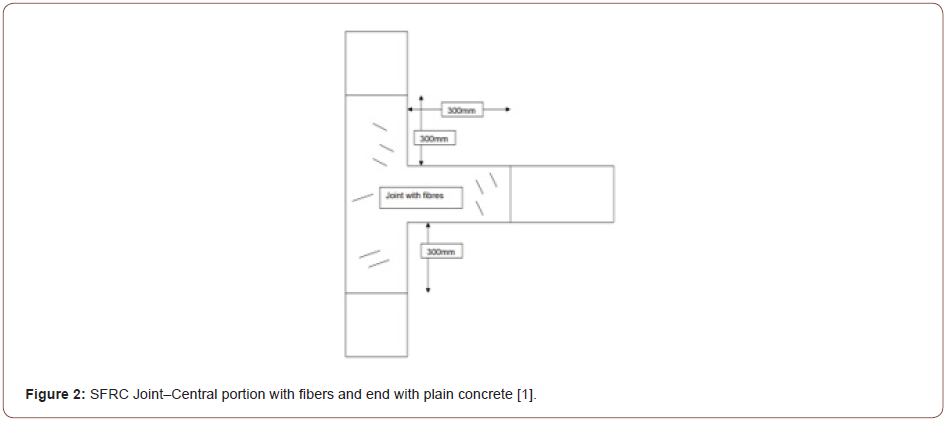

For testing purpose joint was casted as shown in the (Figure 1) with hooked steel fibers. The steel fibers were not added to the whole section but to a part of beam column joint that is in the central section up to 750mm both in column and beam. A total volume of 0.10m3 steel fibers were used and the central joint was casted with fibrous concrete while the rest of the section was casted with the plain concrete (Figure 2) [1].

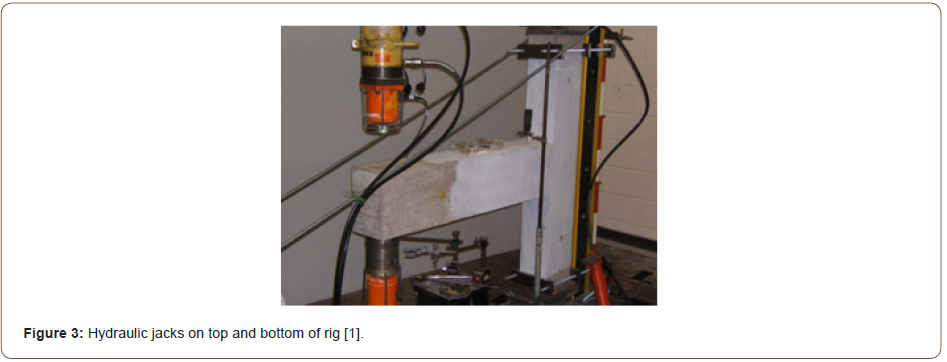

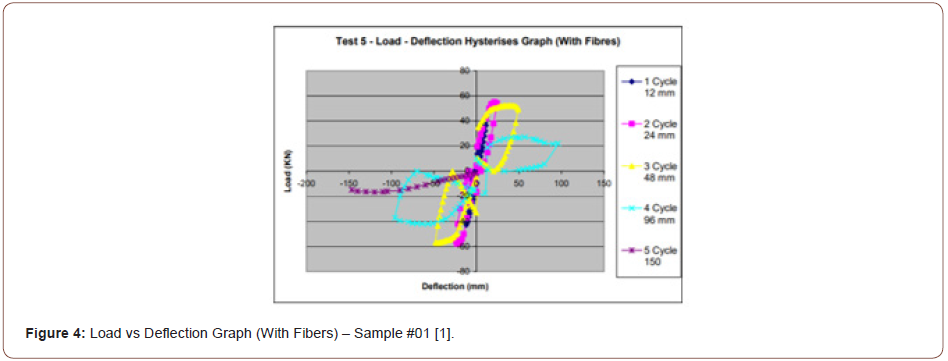

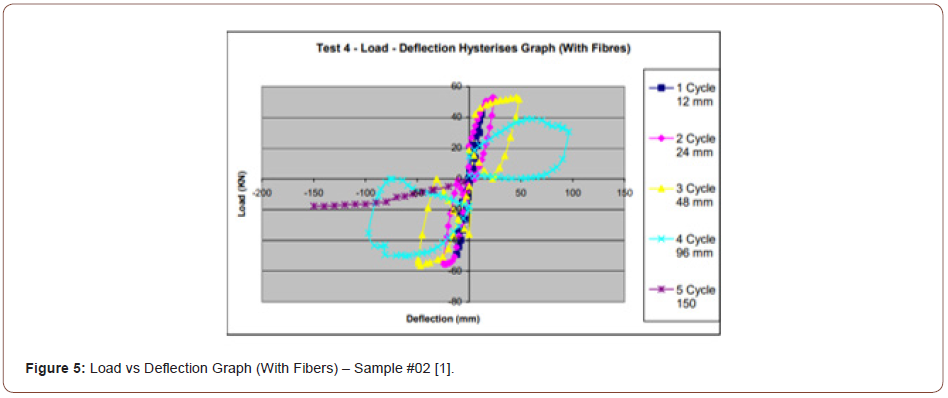

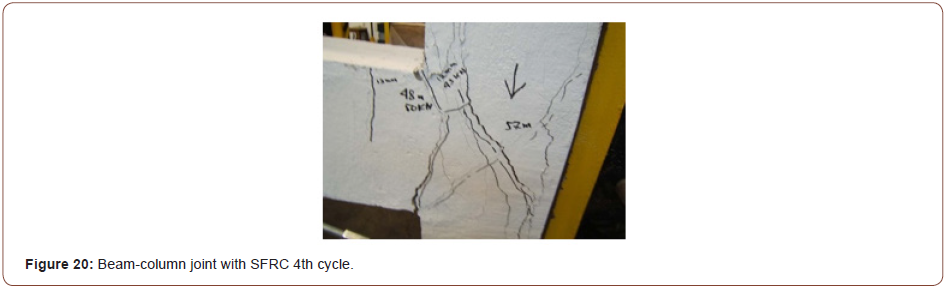

With the help of hydraulic jack, a cyclic loading (earthquake loading) was generated at the top and bottom of the rig (Figure 3). The top hydraulic jack was bolted to the top strong beam loading that was further bolted to two vertically steel columns. The loading plate was then secured to the strong beam. Next, the load cell was placed in the gap between the jack and beam. The jack was extended just enough so that the load cell would then be held in place (Figure 3). Similar procedure was adopted for second hydraulic jack, which was placed at the ground level [1]. During this experimental study, it was discovered that minor cracks started to appear in the second cycle of the cyclic loading, and it is obvious that after increased loading conditions the depth of the cracks appeared to be increased although the joint with steel fibers failed at much greater load as compared to the joint without steel fibers (Figure 4,5).

Seismic resistance

Specimens with SFRC took more loads that plain reinforced concrete (RC). During the initial cycles, it was noted that there was a very minor difference in the peak load values. However, after the third cycle the specimen showed the maximum peak load value. By the fifth cycle, the conventional joints exhibited a fraction of the maximum load reached by the SFRC joints. Maximum loads reached during the simulated quasi-static earthquake loading. Thus, SFRC samples took a higher peak load as compared to plan reinforced concrete samples.

Results

The results were evaluated in the form hysteresis loop (load vs deflection graph). Representing the Earthquake loading by hysteresis loops is a standard method, which has been widely reported in literature. A hysteresis loop is graph which indicates the response of beam towards loading conditions in different cycles. The evaluated data from the experimental study was extracted to hysteresis loop (Figure 4,5). As this research is about the modelling of steel fibers reinforced concrete beam column joint so the load vs deflections graphs are only shown for 2 different samples of SFRC beam column joint.

Materials Properties for the Model

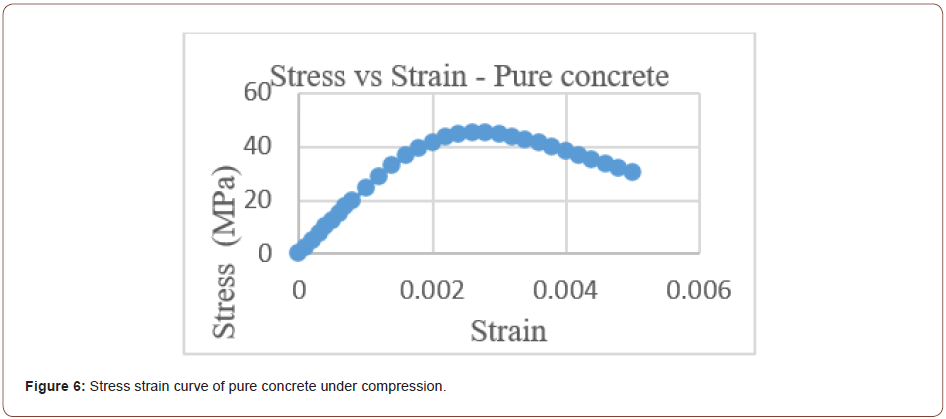

Pure concrete

Constitutive law of S. Majewski model and Eurocode 2: Design of Concrete structures, Part 1-1 is used to determine the yielding point and gives a comparative good relation for stress vs strain for compressive behavior of concrete [10,11]. A concrete of compressive strength(𝑓cu) of 45 MPa was used in experimental work. Modulus of elasticity of concrete (Ec) and concrete tensile strength (fct) were calculated.

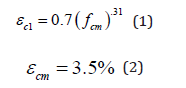

• Where fcu and fcm is given in MPa.

• And Ɛcm is in GPa.

Other values defining the location of characteristics points on the graph are strain Ɛc1 at average compressive strength and ultimate strain Ɛcu.

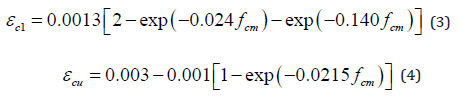

The formulas (1-2) are applicable for concrete of grade C50/60at the most, these equations are given my eurocode-2 for the determination of average and ultimate strain respectively. Later, Majewski proposed two equations for the more accurate determination of average and ultimate strains respectively. On the basis of experimental results Majewski proposed the following approximating formulas.

Knowing the values from the above equations one can determine the points which the graph should intersect with the help of equation given my Eurocode-2 (EN 1992-1-1).

With the help of Majewski and eurodcode-2 the above strain vs stain curve is determine.

Fibrous concrete

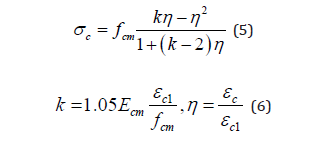

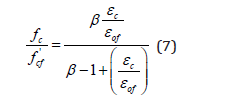

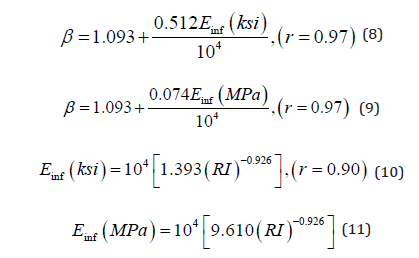

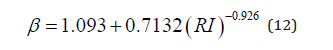

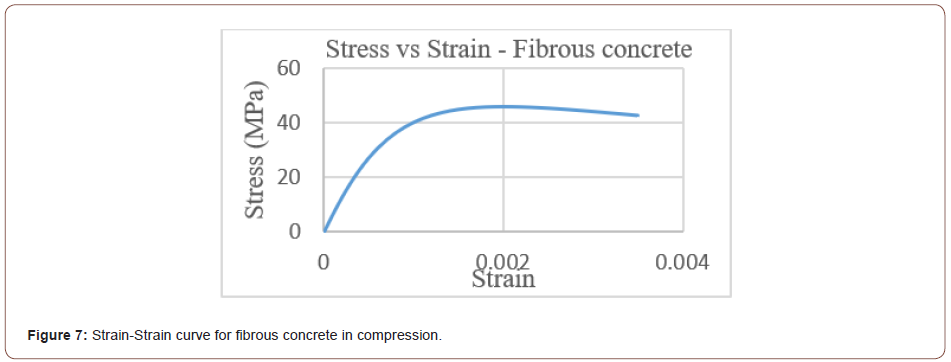

The stress-strain curve for fibrous concrete is determined with the help of empirical relations given by A. Samer Ezeldin,1 Associate Member, ASCE, and Perumalsamy N. Balaguru,2 Member [12], ASCE as follows.

Where,

= compressive strength of fibrous concrete.

= Strain corresponding to the compressive strength.

fc, Ɛc = Stress and strain values on the curve respectively.

β = Material property.

Equation (5) is used determine the compressive strength for a given compressive strength of fibrous concrete, only two values are needed that is β and Ɛof.

To determine β for hooked steel fibers the following equations were found best to describe the relation [20].

From equation 8-10,

With the help of these equation, the stress strain curve obtained for fibrous concrete in compression is as. (Figure 7).

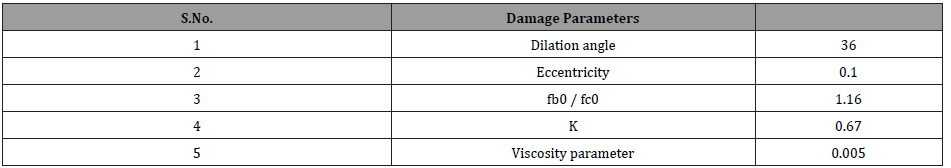

Damage parameters

Table 1: Damage parameters for CDP model.

Concrete damage plasticity a built-in module in ABAQUS is used to model concrete and with the help of hit and trail following damage parameters were determined (Table 1).

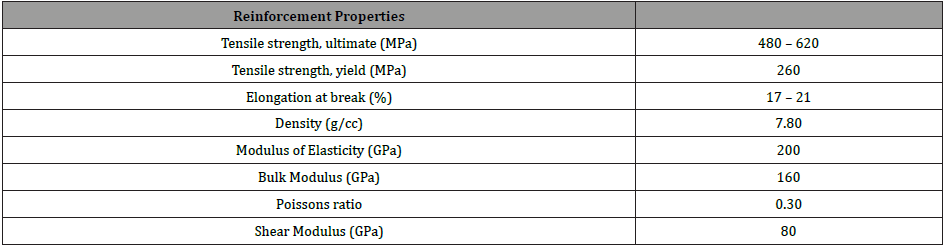

Steel reinforcement

The used reinforcement was represented as an elastic material in tension and compression. It was obtained from experiment that the elastic modulus of steel (Es) was equal 210 GPa for all types of bars. For longitudinal bars in beam and column, the yield stress (fy) was measured in the experimental study and the value obtained was 500 MPa. While stirrups of both beam and column have a yield stress of 500MPa.These values were used in the FEA model. A Poisson’s ratio of 0.3 was used for the steel reinforcement. The bond between reinforcement bars and concrete was assumed as a perfect bond (embedded region). The material properties of reinforcement bars as per ASTM A516 for the numerical simulation are listed (Table 2).

Table 2: Properties of reinforcement.

Steel fibers

Product type of DRAMIX 4D 65/35BG were used in the experimental study having 60 Kg/m3 (0.92% volume fraction). They were hooked end and had a length of 35 mm and a diameter of 0.55-mm resulting in an aspect ratio of about 65.

Whose qualities meets ASTM A820 and ISO 9001.

Computer software

This research is carried with the help of computer software used for finite element analysis that is ABAQUS. Although there are number of computer software’s are available for finite element analysis, but the one specific used for modelling of beam column joint in this research is Abaqus/Explicit. There are number of reasons for choosing this software, but the reasons are for its efficiency in static analysis and dynamic analysis along with its accuracy in carrying out the nonlinear analysis calculations. Also, this software is efficient for the application of different types of loading condition which in this case is cyclic loading, which in this case is cyclic loading.

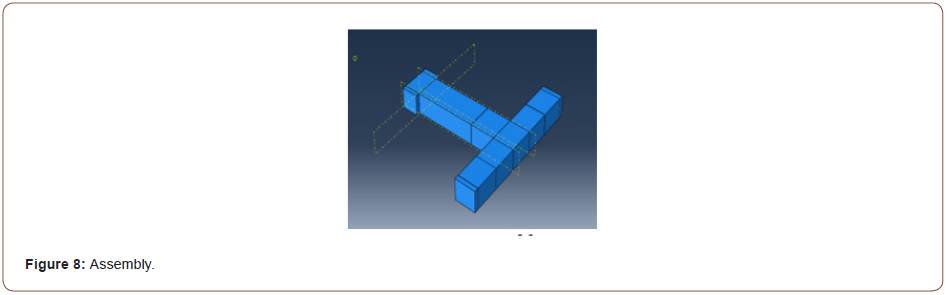

Modelling

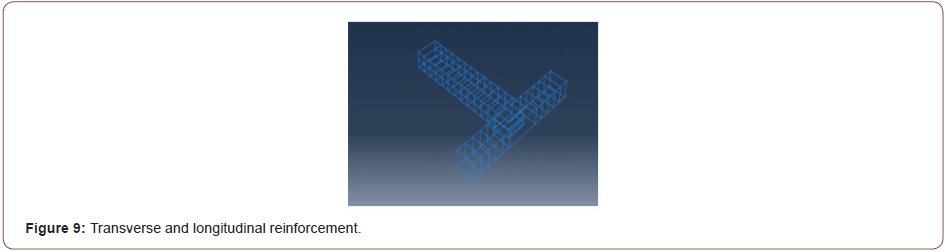

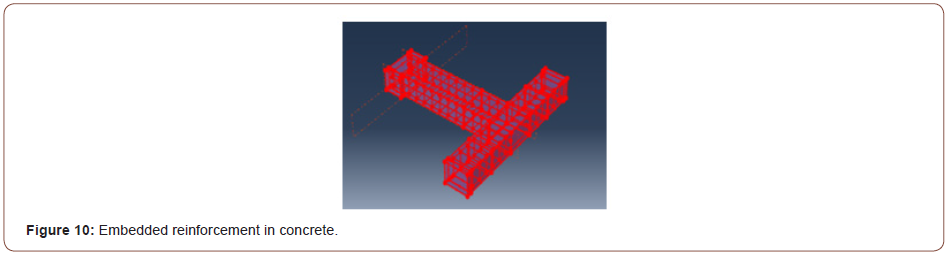

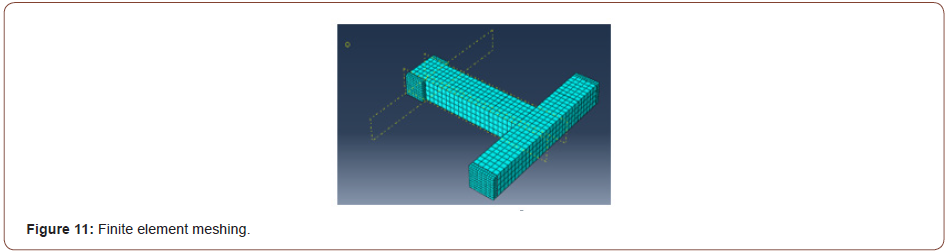

There are number of functional units called as modules are available in ABAQUS and each module serves a separate function, which are only relevant to the specific part of the modelling. For example, the part module is to make the appropriate geometry of the all the parts of the model and property module is used to generate materials in ABAQUS and assign properties to them etc. With the help of all the module available in Abaqus a T-shape joint (beam column joint) was model. A geometrical T-Shape joint was created, along with longitudinal and transverse reinforcement in part module (Figure 8, 9). Afterward the compressive and tensile behavior of concrete was model in concrete damage plasticity model in property module and material for reinforcement and steel fiber was also created. Then reinforcement was embedded in the concrete joint with the help from interaction module (Figure 10). A mesh size of 50 was assigned to parts of the joint to have a node on another on joint section (Figure 8-11).

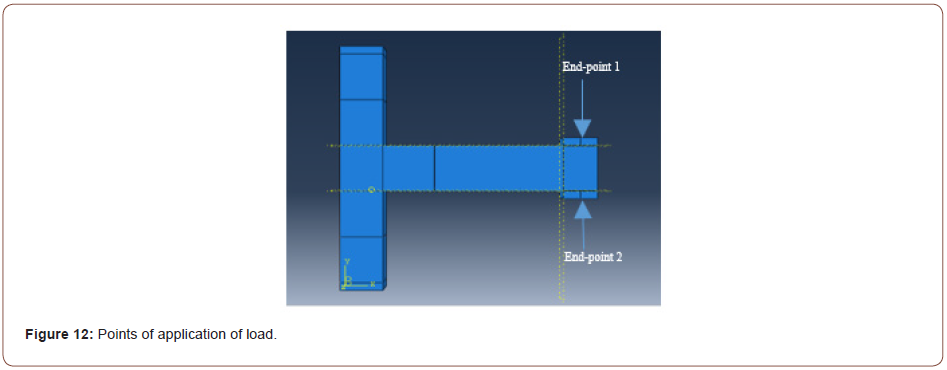

Earthquake cyclic loading

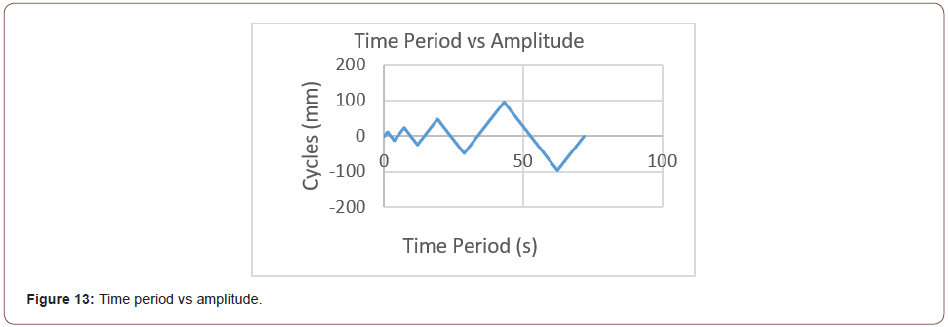

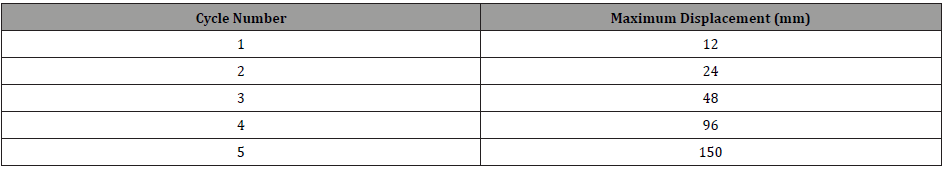

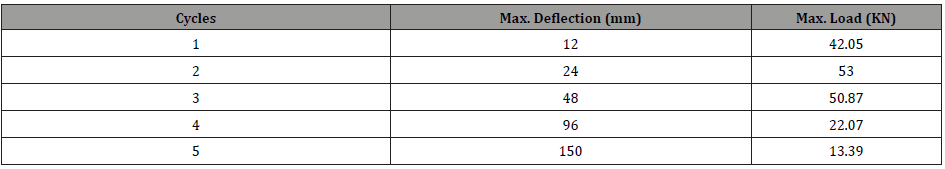

Earthquake loading consisted of five different cycles, and each cycle was carried out with strain-controlled non-linear analysis. Loads of different magnitude in form of displacement was applied on the endpoint 1. The displacement for each cycle was increased on the endpoint as performed in the experimental study. Moreover, the load was applied on end point 1 in downward direction as well as in upward direction (Figure 12). Which represented a complete phenomenon of one complete cycle (Table 3).

The applied load in form of displacement in both directions will represent the cyclic earthquake loading to obtain the load, crack pattern and stresses. The obtained results will be plotted in the graphical forms.

Procedures for Analysis

Non-linear static analysis

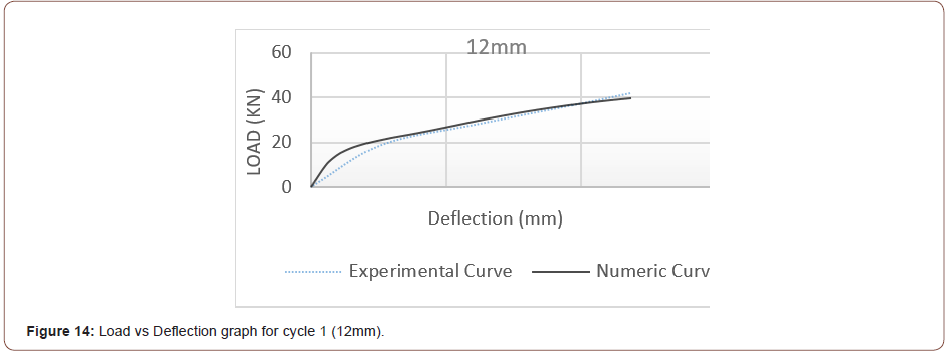

For plastic behavior of the beam column joint, non-linear static analysis was carried out. The plastic analysis was maintained due to non-linear behavior of beam column joint in the cyclic earthquake loading, due to which the material yields and completely shows a non-linear behavior. One of the most important reason for non-linear behavior is that both steel and concrete have different characteristics and properties due to which these two behaves differently to same applied load and also stress-strain curves will have no linearity, which clearly supports our assumption about the non-linear behavior of the proposed model. Initially a 12mm of displacement was applied on the endpoint 1 to obtain the load vs deflection curve for cycle 1, similarly displacement of 24mm, 48mm and 96mm was applied to obtain the load vs deflection curves for cycles 2, 3 and 4 respectively. Afterwards, amplitudes were created with respect to time (Figure 13) and a cyclic loading was applied combines of all the cycles to obtain the crack pattern. It is believed that this type of analysis will help in determining the non-linear static behavior of beam column joint.

Non-linear dynamic analysis

It is an important part of the research to be conducted successfully because this will represent the real earthquake behavior of the joint towards the actual earthquake loading, which will be carried out at later stages. But at this stage a part of it was carried out for the visual comparison of model with the experimental study.

Results and Discussions

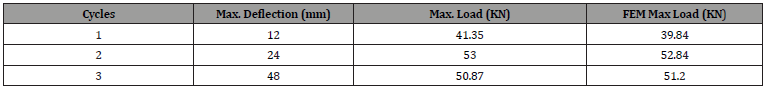

In this section of the research the results obtained through analysis carried out via ABAQUS FEM software are compared with the experimental results conducted by [1]. The beam column joint was analyzed in ABAQUS and results are compared with the experimental hysteresis loop [1]. The hysteresis loop that is load vs deflection curve of experimental study for each cycle (Figure 4, 5). With the help from the get data digitizer software peak load values and peak deflection values have been extracted and transferred into a table (Table 4).

Non-linear static analysis

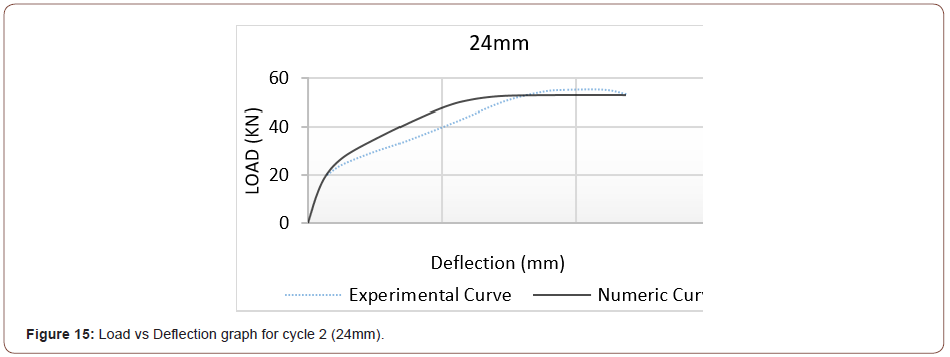

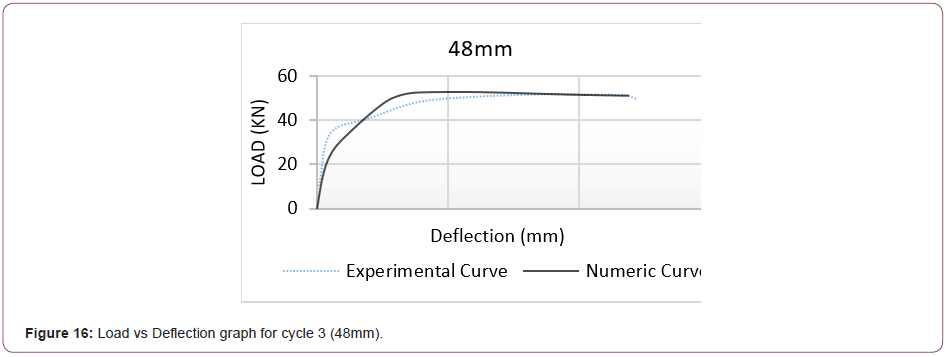

The load vs deflection curves for cycle 1, 2 and 3 against the given maximum deflection as done in the experimental study are obtained from the simulation of the proposed beam column joint and compared with the experimental study (Figure 14-16).

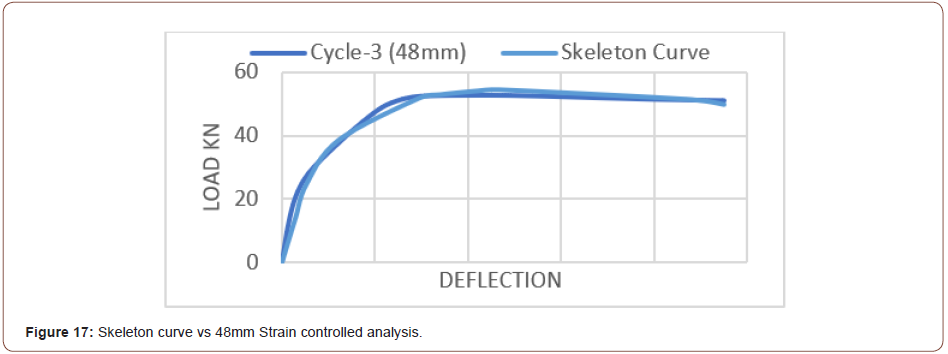

For first three cycles, the simulated curves and peak values comparable with the experimental study having an error of less than 5% which is generally acceptable. So, with the help of these comparisons the simulated result is compared with the skeleton curve for the first 3 cycles (Figure 17).

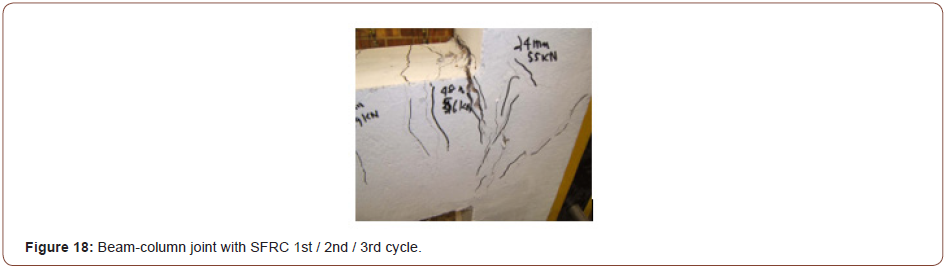

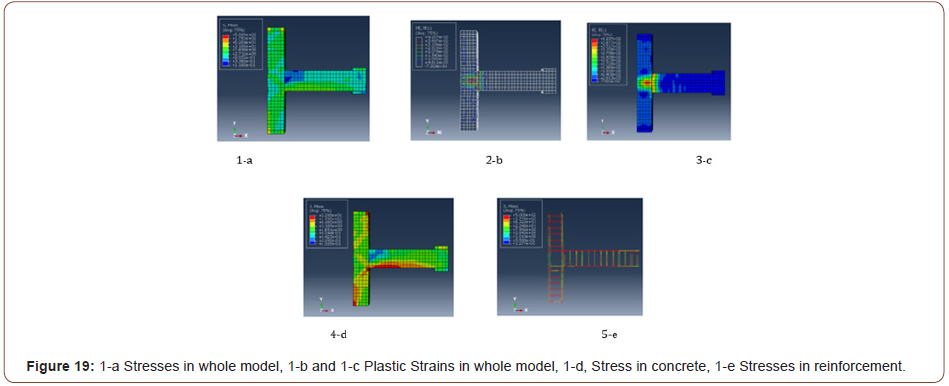

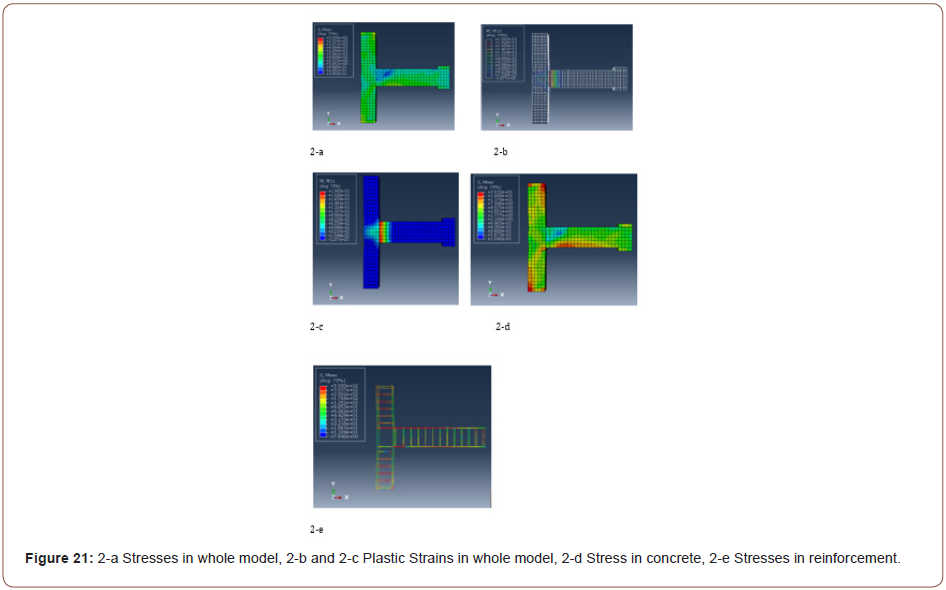

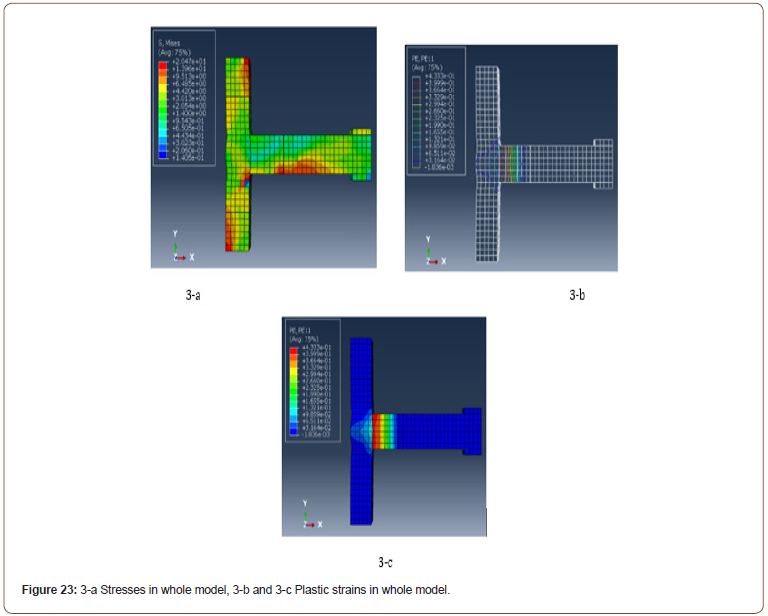

Non-linear dynamic analysis

Non-linear dynamic analysis is a planned future research, which itself is a very complex phenomenon and will be done but a part of it was carried out to do the visual comparison of simulated model with the experimental study. The visual comparison is done on the basis of the maximum stresses generated, plastic strains and crack pattern and crack location (Figure 18-23).

The comparison in (Figures 18-23) is done on the basis of visualization and it can be visualized that the maximum stresses are generated near the join and in the joint region also maximum extent of damage is these location and if visual comparison is done on the basis of stress with the experimental study it can be visualized the stresses generated in simulation are almost in the region that are generated in the experimental study (Figure 18 vs 19 1-d,20 vs 21-2-d and 22 vs 23 3-a). Coming towards the crack’s visual comparison, (Figures 19 1-c, 21 2-c, 24 3-c) and (Figures 19 1-b, 21 2-b, 23 3-b) are showing the max cracks location and crack pattern obtained from simulation and if visual comparison is done on the bases of crack location and crack pattern it can be visualized that the location of maximum cracks are generated and its pattern in experimental study is almost nearly same as obtained from the simulation (Figure 18 vs 19 1-b & c,20 vs 21-2-b & c and 22 vs 23 3-b & c).

Conclusions and RecommendationsConclusions

A Reinforced Concrete Beam Column Joint with Steel Fibers was modelled in ABAQUS v6.14 to perform a finite element analysis and then compare the results with the experimental study for cyclic earthquake loading. To study the non-linear behavior of the joint towards the cyclic loading three types of analysis were carried out. 1. Non-linear static analysis, 2. Non-linear dynamic analysis, 3. Cracking pattern.

The research is very vast and diverse but the main conclusions that are drawn are as follow,

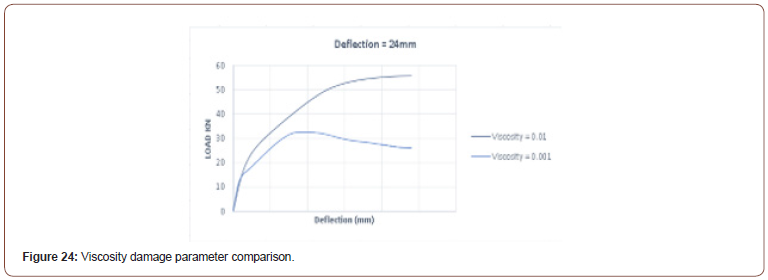

The load vs deflection curve is immensely influenced by any change in the damage plasticity parameters, e.g., considering the viscosity parameter (Figure 24).

Post tensile strength of fibrous RCC beam column joint is greater than pure RCC beam column joint as done in the experimental study.

The cracked formed in the first cycle was gradually widen up due to repetition of cyclic load and it was noticed that the major cracks started to appear after the third cycle.

The occurrences of the cracks are usually due to many reasons, but the most important reason is the pulling and pushing of the reinforced steel bars.

The cracks are generated in according with stresses and strains generated in the model. The simulation results are in line and in accordance with practical work with more than 90% accuracy comparison. • Recommendations Eurocode-2 represents the modelling of pure concrete similarly a code can be developed for modelling of fibrous concrete. After comparing the results, it is recommended that the joint with fibrous concrete should be considered in design as it showed more post tensile strength and maintaining the integrity of joint. Extensive study for non-linear dynamic analysis can be carried out for the proposed beam column joint, which itself is a very complex phenomenon. Extensive for real seismic behavior of different structural members and parts can be carried out using number quasi- static loading Extensive study on cracks location and crack pattern can be done using different built in models and modules in Abaqus. Steel fibers of high aspect ratio should be used to reduce crack width.

To read more about this article...Open access Journal of Civil & Structural Engineering

Please follow the URL to access more information about this article

https://irispublishers.com/ctcse/fulltext/sfrc-modelling-and-non-linear-analysis-of-beam-column-joint-under-cyclic-loading.ID.000671.php

To know more about our Journals...Iris Publishers

To know about Open Access Publishers

No comments:

Post a Comment