Authored by Yimer Hassen*,

Abstract

Easy care finishing of textile materials is one of textile chemical finishing processes to make cellulosic textile materials crease free and dimensionally stable in its service life or during wear. There are different types of crosslinking agents for easy care finishing of cotton fabric. Among these, 1,2,3,4-buthanetetracarboxylic acid is the most effective and formaldehyde free crosslinking agent. On the other hand, woven cotton fabric treated with reactive dyes to give color to textiles. It reacts with fiber in presence of alkali and forms covalent bond with hydroxyl group of cellulosic fibers. In this study, therefore, investigates the effect of covalent bond formation between reactive dyes and cellulose fiber on crease angle recovery and washing shrinkage percentage properties after treated with BTCA crosslinking agent. Initially, cotton fabric was treated with reactive dyes using cold-pad-batch method and followed by easy care finishing for both bleached and dyed fabric using pad-dry-cure method. The application of Bi- and Tri- functional reactive dyes reduces the total crease recovery angle and Tri- functional reactive dye improves the washing shrinkage percentage properties of cotton fabric.

Keywords:Cotton fiber; Reactive dyeing; Crosslinking agent; Crease recovery angle; Washing shrinkage; Strength

Introduction

Finishing is generally the last stage of modern textile production. Its goal is to convert the bleached, dyed or printed cellulosic or other fabrics by mechanical and chemical treatment into a suitable state for sale and making-up. Easy care finishing also known as resin finishing, wash-and-wear finishing or durable finishes is the one among different techniques of chemical finishing of textiles. This method of finishing helps cellulosic fibers to maintain a stiff, just ironed or wrinkle free appearance through the lifetime of the article despite various disadvantages such as strength losses, shade changes and reduced whiteness [1,2]. The primary cause of the shrinkage and crease formation of cellulosic fibers is the fact that these fibers can readily absorb moisture. This absorbed moisture facilitates internal polymer chain movements in the amorphous fiber areas by lubrication. It disrupts the internal hydrogen bonding between these polymer chains. When a moisture laden cellulosic fiber is stressed, the internal polymer chains of the amorphous areas are free to move to relieve that stress. Then, hydrogen bonds can reform between the polymer chains in their shifted positions, in effect, locking in the new configuration. With no restoring forces available, a newly formed shrinkage or crease will remain until additional processes (for example ironing) apply adequate moisture and mechanical forces during to overcome the internal forces [3,4]. The swelling of cellulosic fibers by moisture can be reduced by the application of self-crosslinking agents and products which reacts with the cellulose molecules. In recent days, crosslinking agents from very low formaldehyde to zero formaldehyde release have been developing. N,N’-Dimethylol-4,5-dihydroxyethylene urea (DMDHEU), N,N’-Dimethyl- 4,5-dihydroxyethylene urea (DMeDHEU) and 1,2,3,4-Butanetetracarboxylic acid (BTCA) are some of the crosslinking agents used recently [3,5-10]. On the other hands, dyeing is the application of color to a textile material. Reactive dyes are one of among different groups of dyes depending on the application methods. Reactive dyes are a highly successful class of modern synthetic dyes owing to their wide shade gamut, their flexibility in application, and the excellent fastness properties they offer when dyed on cotton and other textiles. Reactive dyes may be loosely defined as chromophores that contain pendant groups capable of forming covalent bonds with nucleophilic sites in fibrous substrates during the fixation steps [10]. Bi-functional and Trifunctional reactive dyes which are characterized by the presence of two or three reactive groups were used in this study. Both of the dyes have been applied at room temperature in alkaline condition followed by fixation and rinsing process. The main purpose of this research work is to find out the effect of reactive dyeing on total crease recovery angle, washing shrinkage percentage and other important and related textile properties of cotton fabric in the application of crosslinking agents [5,11,12]. In this study we have focus to evaluate the influences of reactive dyes on CRA and washing shrinkage percentages of the fabric. In addition, we have seen its effect on different other useful textile properties, such as, strength, flexural rigidity, abrasion loss and air permeability of woven cotton fabric [1,12,13]. Furthermore, most finishes are applied to fabrics such as woven, knitwear or nonwovens. It is also possible to apply finishes to other forms of textile materials, such as fiber, yarn or garment. Therefore, this research work results could be the foundation to be applied on cotton fiber and yarn stages to study or investigate the differences and to optimize processes.

Materials and Methods

Fabric

Mercerized full bleached cotton fabric with the following specification was used: end/cm, 38; picks/cm, 30; and weight, 130 g/m2

Chemicals

1,2,3,4-buthanetetracarboxylic acid crosslinking agent , Trifunctional orange reactive dyestuff , C.I. Reactive Black 5 reactive dyestuff, sodium carbonate and Sodium hydroxide solution 33% alkaline agent were used in treatments and after washing processes.

Methods

In this investigation, initially, woven cotton fabric has been treated with Bi- and Tri- functional reactive dyes in alkaline condition. The dyeing has been done in a cold-pad-batch method. The dyes and the alkaline agents are prepared separately to avoid hydrolysis of the dyes. All were mixed up only just before padding. It stayed for 24 hours at room temperature for fixation followed by rinsing and soaping. Then, Bleached and dyed sample were treated with 100g /l of BTCA and cured at 130 °C for 3 min using pad-dry-cure method. Samples had 90% average pick-up values. In this test, CRA (Back and face or warp and weft directions), washing shrinkage (in both direction) and other important textile properties has been measured. In each test five samples have been measured. Abrasion resistance tester, FX-33 00 TEXTEST air Permeability tester, washing shrinkage standard ruler, washing laundry, Stiffness measuring inclined plane, weighing balance, TruBurst, water capillary rise, CRA, oven dryer, curing machine and Padder were the machines or instruments used in treatment and testing of the fabrics.

Results and Discussion

Total crease recovery angle

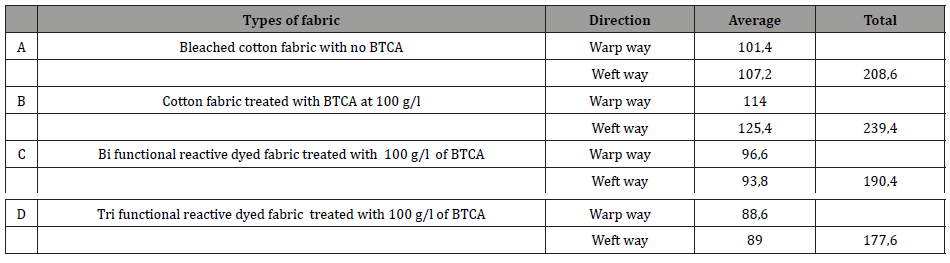

Crease resistance of fabric is the ability of the fabric to prevent the formation of wrinkles or creases on the surface of the fabric during various uses or process. The crease resistance of the fabric is expressed in the term of crease recovery angle. The total crease recovery angle is the sum of warp and weft crease recovery angles. According to ISO 2313-1972(E) method, twenty specimens have been measured from both warp and weft way of the fabric. Each sample has 15 mm by 40 mm size. It has been loaded with 1kg for five minutes and five more minutes for recovery after unloading. The measurement has been done for both faces of the fabrics. All the results are in nearest degrees. As shown in Figure 1 and Table 1, the total crease recovery angle increases as the concentration of BTCA increases for bleached fabric and decreases for reactive dyed samples [1,14-16].

Table 1:Total crease recovery angle of woven cotton fabrics treated with BTCA and reactive dyes.

Washing shrinkage percentage

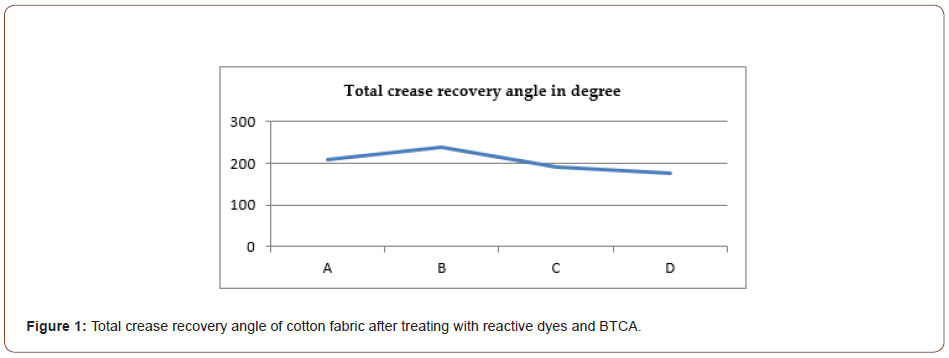

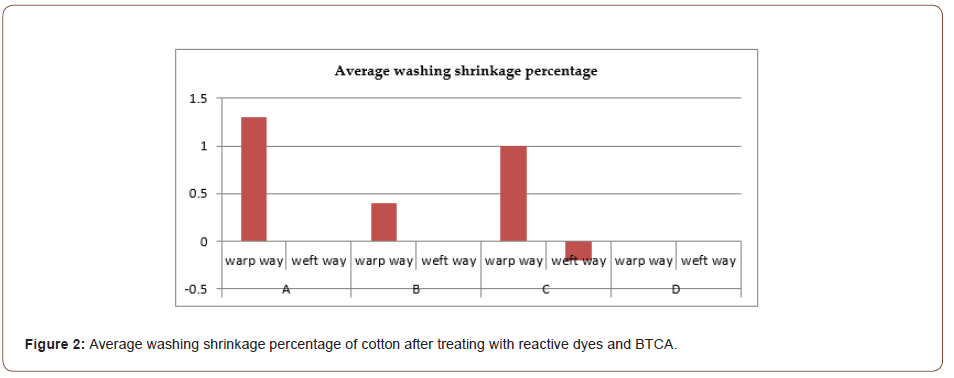

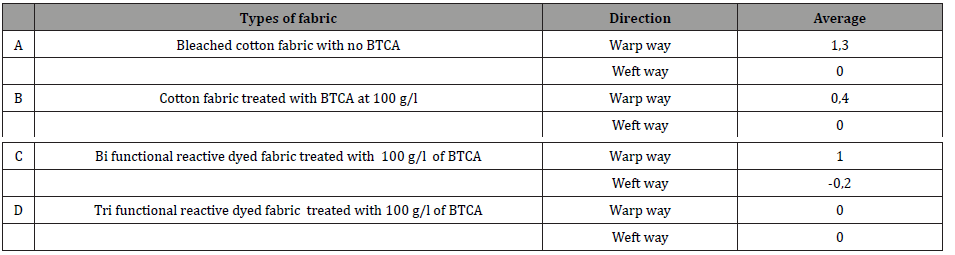

Measuring Washing shrinkage percentage is used as a factor that determines the change in length and width of the fabric after washing. Shrinkage has great significance because any expansion or shrinkage can cause deformation of the product, which could be a severe concern for the end-user. In this test, according to ISO 6330:2012-08, washing agent (40 g) and Sodium carbonate (20 g) have been used for 2 kg of the woven cotton fabric. In addition, washing was performed under 60 °C for 75 min. of washing time. As shown in Figure 2 and Table 2, nearly no washing shrinkage has been seen in Tri-functional reactive dyeing. On the other hand, washing shrinkage and stretch has been increased in Bi-functional reactive dyeing as compared to cotton fabric treated with only BTCA [1,14].

Table 2:Average washing shrinkage percentage of woven cotton fabric fabrics treated with BTCA and reactive dyes.

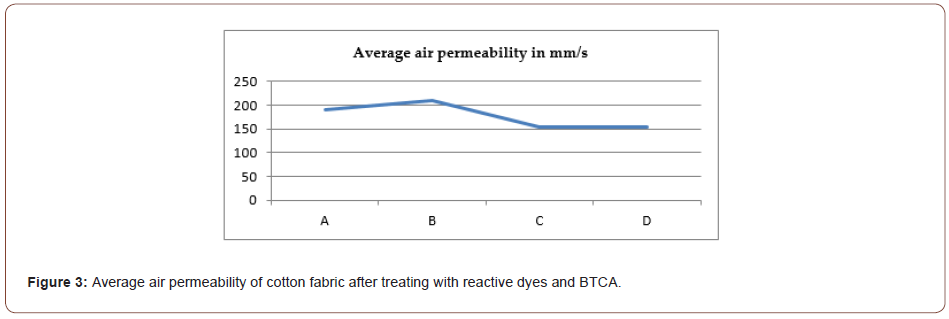

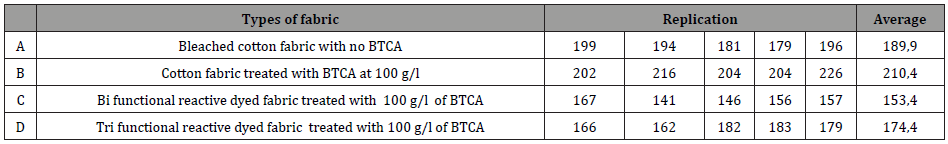

Air permeability

Air permeability is the rate of air flow passing perpendicular through a known area under a prescribed air pressure differential between the two surfaces of a material. It is a measure of how well a fabric allows the passage of air through it. It is assumed to be that the possible formation of 3D structure of crosslinking agent formation than reacting with the cellulosic material will reduce the air permeability properties of cotton fabric. In this test, according to DIN EN ISO 9237 method we have used air permeability testing machine with a diameter of 20cm2 and pressure of 100Pa. The measurements are in mm/s. As shown in Figure 3 and Table 3, the air permeability of woven fabric is higher when the fabric treated with only BTCA whereas it is reduced in both reactive dyeing [14] .

Table 3:The average air permeability of woven cotton fabric fabrics treated with BTCA and reactive dyes.

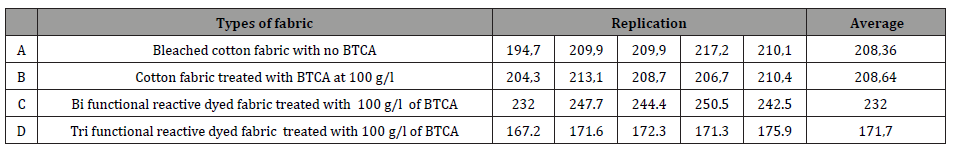

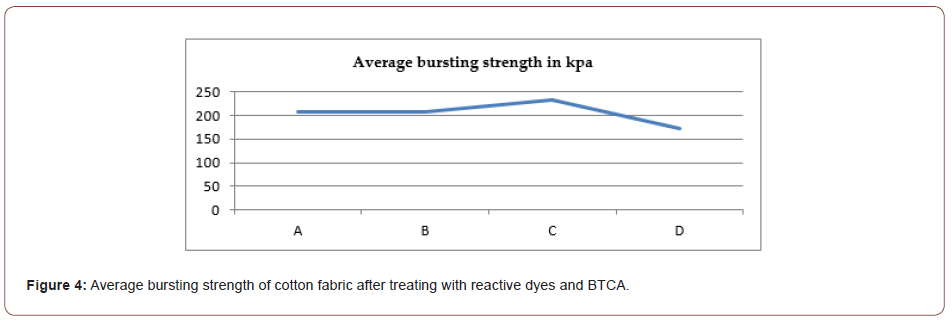

Bursting strength

Bursting strength is the force that must be exerted perpendicularly to the fabric surface to break off fabric. Strength of the fabric is an important property that decides and influences all other performance properties of the woven or knitted fabrics. Consideration of the strength of the fabric is very essential while selecting the appropriate fabric for the intended garment or end uses. According to ISO 13938-1:1999(E) method we have taken five tests diagonally for each sample to represent all the threads in different parts of the fabric with 600kpa clamping at pressure rate of 13 and 10 in kpa for Bi- and Tri- functional reactive dyes respectively. TruBurst2 instrument was used for measuring the strength of the samples. All the measurement results are in KPa. As shown in Figure 4 and Table 4, the strength of the material was improved in Bi-functional and reduced in Tri-functional reactive dyes [17].

Table 4:Bursting strength of cotton fabrics treated with BTCA and reactive dyes.

Abrasion resistance

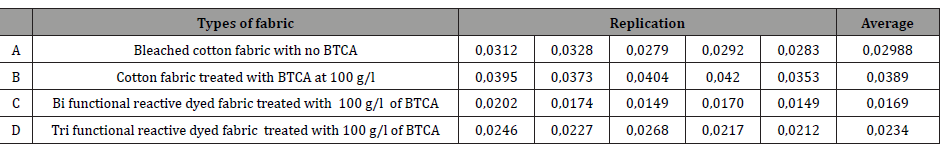

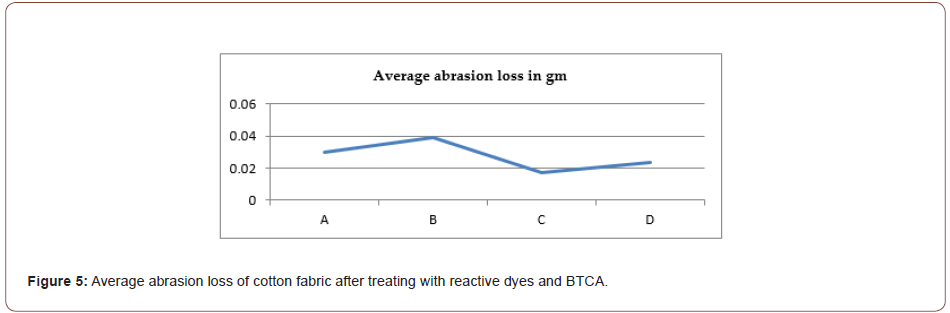

Abrasion resistance is the ability of a fabric to resist surface wear. Abrasion is the physical destruction of fibers, yarns, and fabrics resulting from the rubbing of a textile surface over another surface. In this test, 11cm by 11cm sample size cotton fabric has been used. The Abrasion instrument has been set to 3000 rpm for 30 s for each sample. The weight differences have been measured in grams for each. As shown in Figure 5 and Table 5, the abrasion loss increased for fabric treated with BTCA as compared to untreated cotton fabric. And, Tri- functional reactive dye has higher abrasion loss as compared to Bi-functional dyed fabric. But, in general, dyed fabric with Bi- and Tri-functional reactive dyes have less abrasion loss as compared to bleached and fabric treated with BTCA [15,16,18].

Table 5:The average abrasion loss of cotton fabric in grams fabrics treated with BTCA and reactive dyes.

Flexural rigidity

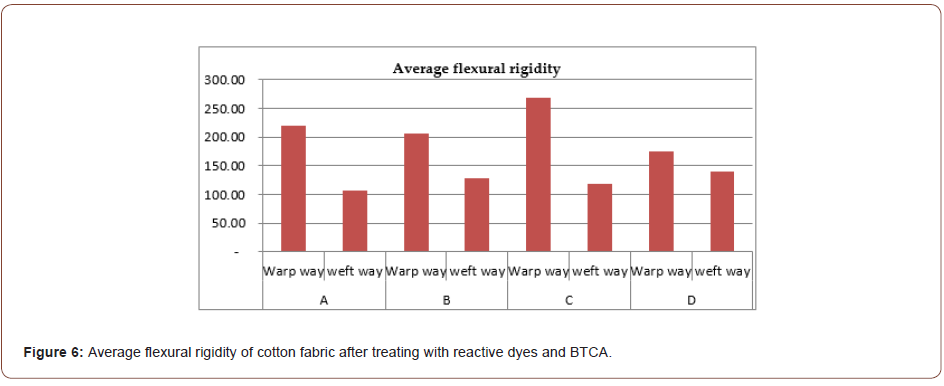

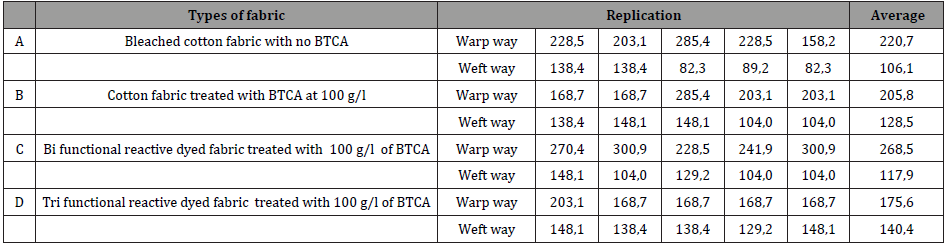

Flexural rigidity is a measure of stiffness associated with handle. Fabric stiffness and handling is an important decision factor for the end users. The degree of fabric stiffness is related to its properties such as fiber material, yarn, fabric structure and type and method of chemical finish. Three-dimensional crosslinking structure against to the reaction with cellulose determines the level of fabric stiffness properties. 20cm by 4cm specimen size has been taken from both ways of the woven fabric. Using DIN 53362, five replications have been taken from each test specimen. Since the finish is generally associated with an increase the weight of the sample, the flexural rigidity must be calculated independent of the sample weight. As shown in Figure 6 and Table 6, the flexural rigidity of woven cotton fabric increases treated with Bi*functional reactive dye and BTCA has higher flexural rigidity in warp than other treatments

Table 6:Average flexural rigidity of cotton fabric in mg*cm treated with reactive dyes and BTCA.

Conclusions

Cellulose fiber especially cotton is the most important kind of fiber because of their numerous advantages. However, wrinkling after washing is one of the main disadvantages. BTCA anti-swelling or crosslinking agent is one of the most formaldehyde free finishing agents for wrinkling free treatment. It disrupts new hydrogen bond configuration by forming strong covalent bond with cotton fiber. Easy care finishing affects the fabric properties because of the crosslinking between cellulose molecules and chemical used in the treatment process. The reactive dye constitutes the most commonly used class for dyeing cellulose fiber. The dye contains a reacting group and this reactive group form covalent bond with the fiber and as integral part of the fiber. Both anti-swelling and reactive dye form covalent bond with cotton fiber. In this investigation we have found that reactive dyeing before anti-swelling treatment reduce CRA, abrasion loss and air permeability of cotton fabric. Bi-functional reactive dyeing improves the strength, resulted shrinkage in warp and stretch in weft direction, and increased the stiffness of the fabric. On the other hand, Tri-functional reactive dye reduced strength and stiffness, and nearly no washing shrinkage on both ways of the fabric. Furthermore, it needs to consider the order of treatment and IR analysis for additional information in research work.

To read more about this article....Open access Journal of Textile Science & Fashion Technology

Please follow the URL to access more information about this article

To know more about our Journals...Iris Publishers

No comments:

Post a Comment