Authored by Wenliang Xue*,

Abstract

The major of textile design at Donghua University is a double bachelor’s degrees program that was supported by Shanghai Academic Degrees Committee, integrating the discipline of design and textile engineering. This study presented a series of practical courses in four semesters from the sophomore year to senior year, to help undergraduate textile design students enhance their product design skills and abilities through experiential learning. The practical curriculum design, implementation process and learning outcomes are introduced in the paper. Results in the study not only reveal the method to embed experiential learning theory into practical courses, but also indicate the importance of learning-by-doing philosophy in higher-education.

Introduction

Textile education has been developed for more than one century. As early as 1900s, textile schools were founded to cultivate skilled textile engineers for the local industry, and at that time, almost all countries in the world had schools, institutions or universities in textiles [1]. In the past, textile education focused on techniques in the traditional textile and clothing industry. The globalization of textile production and trade has changed the landscape of the worldwide textile industry. Especially in China emerging as the world’s main producer of textiles, the textile industry is transforming and upgrading from traditional manufacturing to high-end production with innovation and original design [2]. At present, Cultivation of interdisciplinary talents becomes more and more important. Donghua University as the most famous Chinese university in textiles located in Shanghai, is the former East-China Textile Institute of Science and Technology and have launched some educational reform programs to promote interdisciplinary.

In 2020, Shanghai Academic Degrees Committee approved an interdisciplinary talent training program for textile design major with double bachelor’s degrees integrated disciplines of Design and Textile Engineering. This textile design major aims to cultivate undergraduate students taking textile technology as a foundation, market as a direction and art design as a feature. It is important for textile design students to acquire practical experiences and product design opportunities. Current courses emphasize theoretical teaching rather than practical, so instruction in the classroom is difficult to support students achieve practical ability. In order to train interdisciplinary undergraduate students with a good understanding of design, market and textile technology, a novel practical curriculum system was developed to implement studentcentered experiential learning from the sophomore to senior year, enhancing students’ design skills and abilities through learning by doing.

Experiential Learning Theory

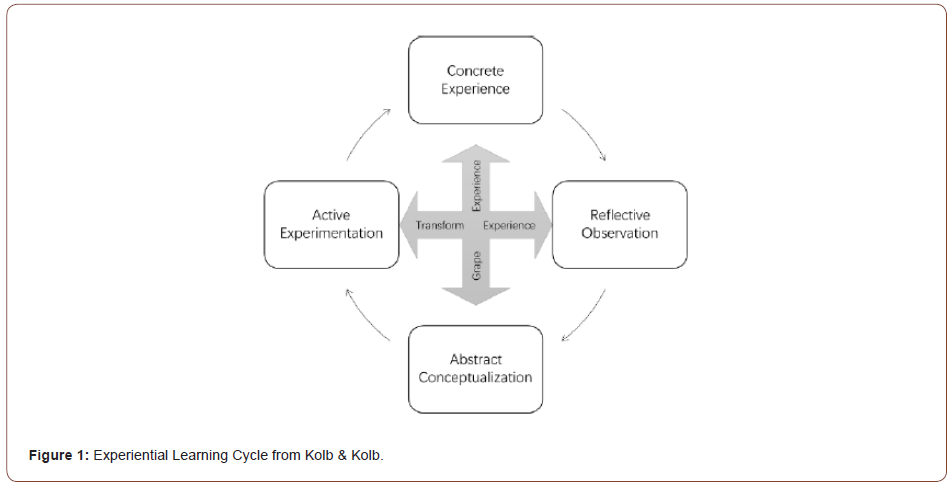

Engineering education has emphasized dynamic, learnercentered experiences that actively engage students with actual materials to connect theoretical knowledge and practical skills [3]. Design is a complex field that involves both practice and academic discipline [4], and design education has responded to increasing complexity and systemic transformations [5]. One educational approach that integrated design and engineering education is student-centered experiential learning. The practical course context described in this paper was informed by experiential learning theory (ELT). Experiential learning is characterized by the practical experiences and embeddedness in real work tasks [6,7]. There are many forms of experiential learning such as case studies, labs, university-industry cooperation, project-based learning, performance-based learning and others, and the activities in all these forms are significantly different from traditional, teachercentered textbook-style ways [8-10]. One of the most popular contemporary experiential learning theories is proposed by David Kolb, who presents an experiential learning cycle [11-12]. As shown in Figure 1, the cycle is divided into grasping experience and transforming experience, including four stages from concrete experience, reflective observation, abstract conceptualization to active experimentation. This experiential learning cycle has been applied in education of different disciplines. Chen introduced the chemical engineering’s Discovery Laboratory at Imperial College London to implement student-centered project-based learning and the course in the lab module was designed based on the ELT of David Kolb [13]. William O’Brien et.al. presented living labs as an opportunity for experiential learning in building engineering education, and assess the teaching and learning effectiveness [14]. An industry-academia strategy was developed to help undergraduate sport management students enhance employability through practical experiential learning in a specific sporting event [15].

In practical disciplines such as textile engineering, experiential learning could be a useful approach to improve student professional and practical skills, especially when education of textile engineering is integrated with design education, practical experiences are extremely essential to enhance the ability to design textile products and solve real-world tasks in the textile and apparel industry. The study in this paper focuses on practical courses that were designed based on experiential learning from spring term of sophomore year (2nd year) to fall term of senior year (4th year).

Practical Course Design and Implementation

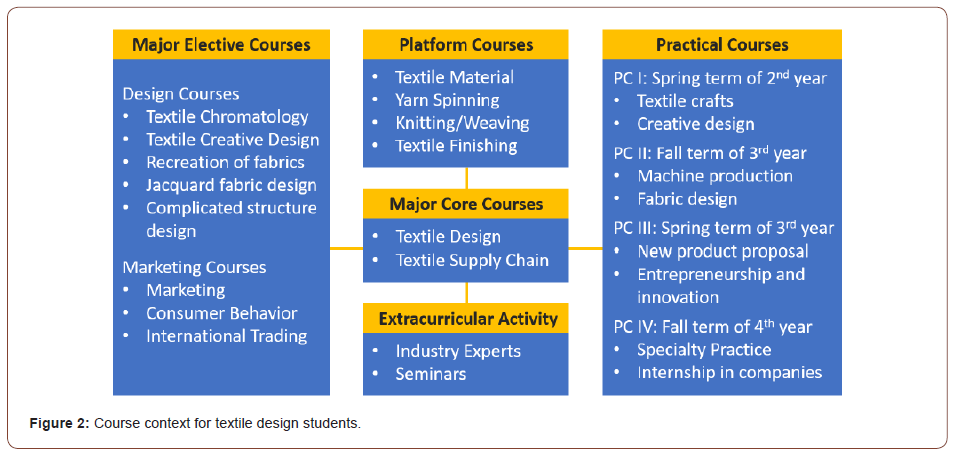

For students majoring in textile design at the College of Textiles, Donghua University, the course module is divided into four parts, including Platform Courses, Major Core Courses, Major Elective Courses and Practical Courses (Figure 2). In addition to courses on textile engineering, Textile Design and Textile Supply Chain are two core courses for textile design major, incorporating the textile product design process from idea generation to product launching, as well as the supply chain process from raw materials to merchandise. Moreover, major elective courses relevant to design and marketing are provided to complement extra fundamental knowledge in design and marketing principles. Students have to complete required credits on those theoretical courses in four semesters from spring term of 2nd year to fall term of 4th year. At the same time, four practical courses are implemented in each semester, and professors in university and experts from industry are invited to give lectures or seminars to students.

Practical course description

The pedagogical design of the four practical courses is based on the Experimental Learning Theory of David Kolb.

• Practical course I (PC I) on Spring term of sophomore year incorporates hand weaving, braiding, hand embroidery, tie-dye, batik and other textile crafts techniques. This course aims at the development of design skills using various materials to form textile products, and experiences of finishing the handmade fabrics help students understand the basic elements of textile structures and their properties.

• Practical course II (PC II) on Fall term of junior year allows the students to implement textile design ideas into physical yarns and fabrics using semi-automatic loom, hand knitting machine and sample spinning machine. Contexts in this course compose of principles and elements in spinning, weaving and knitting, enabling students to experience the product design and development process similar to using industrial facilities.

• Practical course (PC III) on Spring term of Junior year emphasizes entrepreneurship and innovation in textile design. The course incorporates lectures from industry experts for understanding of the new product development process in the industry. According to case studies and experiences obtained from other theoretical and practical courses, the students in groups are asked to provide a proposal, which can present their design ideas with textile technologies, target markets and other strategies for developing the new product.

• Practical course (PC IV) on Fall term of Senior year provides specialty interns in textile companies. Students are organized in groups to complete a 4-weeks internship that a textile design project is offered by the company and needs to be finished by group students.

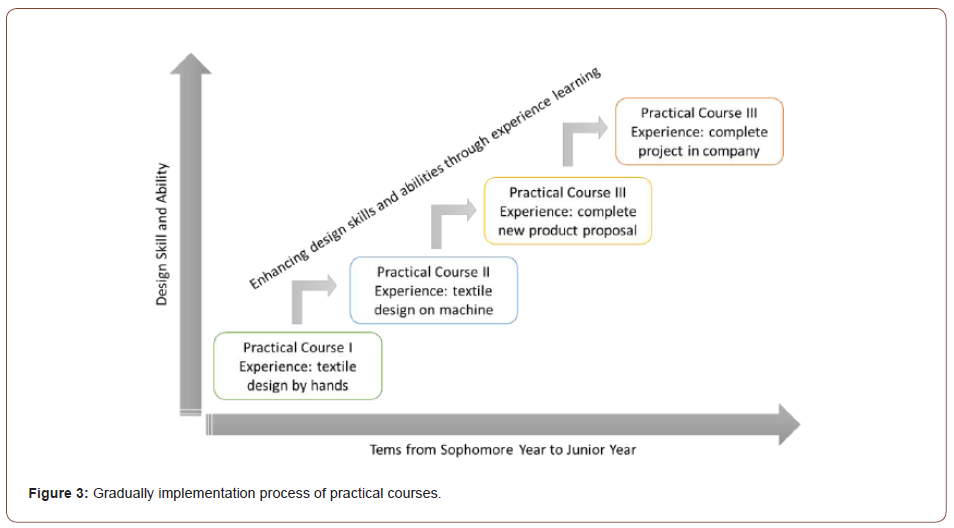

The four practical courses are gradually implemented in four semesters with different levels of complexity. The students can apply the fundamentals of product design and textile engineering in practical courses and then enhance their textile design skills and abilities through in-depth experience learning from cognition, reflection, conception to active practice.

Gradually implementation process

Figure 3 shows the gradually implementation of four practical courses from the spring term of sophomore year to the fall term of junior year, and students’ design ability is increasing with more practical experiences. There were 60-70 undergraduate students enrolled in one practical course for each semester. The performance of students in every practical course was evaluated in the Experiential Learning Cycle (Figure 1) from concrete experience, reflective observation, abstract conceptualization to active experimentation.

In practical course I, eight professors in the College of Textiles at Donghua University joined in teaching the craft textile design courses in two weeks at the end of sophomore spring term, and each professor was in charge of one or two handcraft techniques. In the first week, professors provided information about different textile handcraft skills, and students could learn methods, principles, tools and cases of each craft skill. The students in this stage obtained concrete experiences and reflective observation. In the second week, after thinking about how to integrate multiple skills and materials in textile design, students were required to complete their own handcraft portfolio and present at the end of the course. This means students engage with abstract conceptualization and active experimentation. The assignments in PC I included a report of fabric analysis and two handcrafts. The report was a summative assessment, which was conducted by professors. The handcrafts portfolio that presented by the designer was conducted by both professors and the students themselves. Moreover, to improve students’ motivation, a textile handcraft competition was held when the course was completed, and top 30 handcrafts were elected and exhibited in Shanghai Textile Museum (Figure 4).

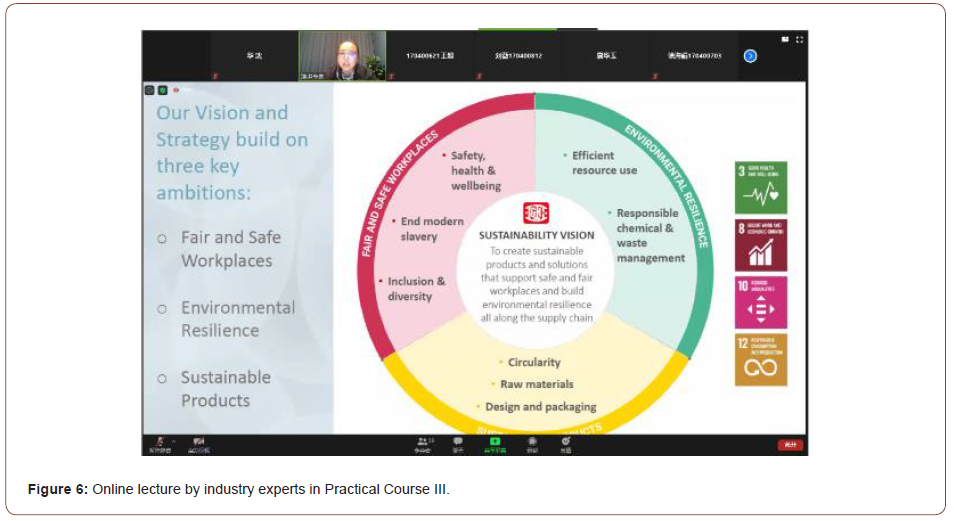

Practical course II was implemented in two weeks at the end of junior fall term, and four professors in the college gave lectures on machine operation, and two industry experts were invited to show some successful commercial fabrics to students. The students went through the experience learning cycle, and created their own designed yarns, woven or knitted fabrics on sample machines. The assessment in PC II was also divided into summative report that indicated how the students completed yarn or fabric samples, and presentation boards that illustrated design theme, inspirations, patterns, structure design and fabric samples. The reports were conducted by professors and the design presentation was evaluated by both students, professors and industrial experts. At the end of the course, those excellent design boards would be exhibited on campus for taking a motivational effect (Figure 5). Practical course III was also implemented in two weeks at the end of junior spring term. Two professors in the college and four industry experts were invited to give lectures on product design and development process. The students could learn and think how textile products were designed and developed in real world. After going through reflection observation and abstract conception in the experiential learning cycle, the students were required to provide a new product proposal and take simulated commercial roadshow, which would be evaluated by industrial experts. This method provides students with exposure in simulated work environment to develop their skills and abilities before graduation (Figure 6).

Previous three practical courses were executed on campus, but the practical course IV that focused on specialty practice was implemented in companies. 5-10 students in one team took a 4-week internship in different companies, which run business on textile manufacturing or textile home/apparel brand. During the internship practical course, each team was required to join in a real project offered by the company and the students were supervised by one professor in the college and one expert/manager in the company. The students could apply knowledge and experiences that they learned from theoretical and practical courses to complete the project. At the end of this course, the students prepared a summary of the project and took a presentation that showed what they did and learned in the internship. A panel of professors with experience in the industry would evaluate students’ learning outcomes (Figure 7).

As David Kolb states that “learning is the best conceived as a process, not in terms of outcomes” [16], the assessment in each practical course has a distributed weightage over the entire learning process instead of just assessing the final report alone. For example, in practical course IV, the participant and intern summary accounts for 40% of the overall mark, whereas the final team report accounts for 40% and evaluation from the company accounts for the remaining 20%.

Learning Outcomes

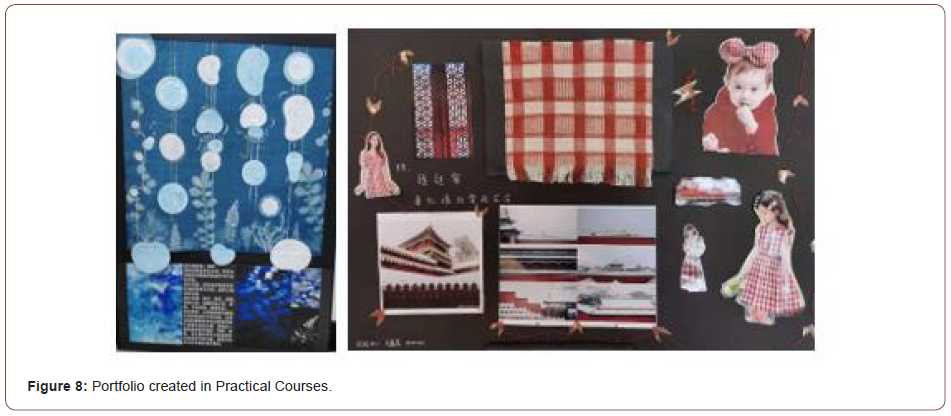

In practical course I and II, following the experiential learning cycle, students need to have concrete learning and reflective thinking of textile design methodology, and then they had to do a design survey to find inspirations. Finally, different materials and producing methods can be used to implement their design ideas into textile products. More than sixty handcrafted textiles and machine woven or knitted fabrics were created by students. Figure 8 shows two student design works, the left one was a recreation of cyanotype fabrics and hand embroidery that inspirated by marine animals, and the woven fabric on the right broad was inspirated by windows of ancient buildings. The students in these courses were responsible for organizing an exhibition in the activity center of the university to show their work. In addition, top 30 design works that were elected by professors in the university and experts in industry could be exhibited in Shanghai Textile Museum for one year.

In practical III and IV, the students have more chances to communicate and work with experts in the industry, and they can learn about the methods and tools used in the real-world product development process. They also gain employment experiences in team work and internship before leaving the university. Moreover, the students in these courses provided more than 20 proposals in textile product design and development, and five of them were applied and funded by National or Shanghai Innovation and Entrepreneurship Program for College students (Figure 8).

As reflective teaching helps improve the teaching-learning process, a reflection forum was held at the end of fall semester in each year to discuss how the practical courses carried out in the past year and to obtain feedbacks from students and industry experts. The students highlighted that the practical courses provided experiential opportunities to express their design ideas and learn the real-world projects. Industry experts emphasized that experiential learning integrated university and industry was very essential in university training and allowed students to prepare them for future professional activities.

Conclusions

The use of experiential learning theory (ELT) in the practical courses has helped textile design students to implement the knowledge learned both in textile engineering technologies and design courses to create practical product design solution and produce physical sample products. Also, practical courses based on ELT allow the students to understand the product design methodology and the product development process in the textile and apparel industry. The four practical courses established in the College of Textiles at Donghua University have provided gradually training of students from sophomore year to senior year and have achieved positive feedback from both students and industry experts.

To read more about this article....Open access Journal of Textile Science & Fashion Technology

Please follow the URL to access more information about this article

To know more about our Journals...Iris Publishers

No comments:

Post a Comment