authored by Seongwoo Woo*

Abstract

To enhance the lifetime of mechanical system, parametric Accelerated Life Testing (ALT) as new systematic reliability method suggests evaluating the design of mechanical systems subjected to repeated stresses, based on failure mechanism and design. This newly developed parametric ALT helps an engineer uncover the missing design parameters (or design flaws) of the mechanical system having an effect on reliability during the product developing process. As a result, companies can circumvent product recalls due to the design flaws from the marketplace. As an experiment instance, the redesign of hinge kit system (HKS) in a domestic refrigerator was investigated.

Keywords: Reliability design; HKS; Fracture; Parametric ALT; Design flaws

Introduction

The mechanical products such as automobile, airplane, and refrigerator manage power to achieve a job that requires forces and movement, which produce mechanical advantages by adapting product mechanisms. For example, using the vapor-compression refrigeration system, a refrigerator supplies chilled air from the evaporator to the refrigerator and freezer section. Customers want a refrigerator that have high performance and reliability for multi-functions. Accordingly, a HKS structured as a spring-damper therefore was designed as a consumer want to gently open and close a refrigerator door with minimal effort. If there is design fault in the system when the loads are exerted, HKS may unexpectedly fail in its anticipated lifetime. After recognizing the product failure by parametric ALT, an engineer might most favorably design. This study proposes a parametric ALT as systematic reliability method that can be applicable to mechanical systems. It composes: (1) a parametric ALT plan, (2) a load analysis, (3) a customized ALTs with the design alterations, and (4) an assessment of whether the product design(s) achieves the objective BX lifetime. As an experiment instance, we will discuss as following: the redesign of HKS in a refrigerator.

Parametric ALT in Mechanical System

If there is a wrong design in the product where the (dynamic) loading are exerted, it might suddenly be unsuccessful during its lifetime. After recognizing the market failure by parametric ALTs, an engineer will design the parts such as material pattern to overcome its own loads.

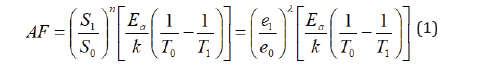

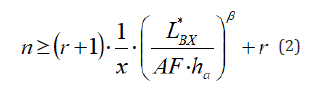

To get the required mission cycle of an ALT, sample size formulation with the AF might be defined as [1]:

Case Study: Reliability Design of a HKS Subjected to Repeated Stresses

As a customer utilizes the refrigerator, one would close its door comfortably. For this purpose, the HKS is newly designed (Figure 1).

From the marketplace, HKS components in a domestic refrigerator were failing due to design problems. Formed on the customer working states, HKS were subjected to dissimilar loading during the operations of the refrigerator door (Figure 2).

To read more about this article...Open access Journal of Modern Concepts in Material Science

Please follow the URL to access more information about this article

To know more about our Journals...Iris Publishers

No comments:

Post a Comment