Authored by Bapan Adak*,

Abstract

Recently, conductive textiles are being utilized extensively in a wide range of smart applications such as sensors, textile batteries, supercapacitors, electrostatic discharge clothing, heating textiles and many more. This review highlights the role of various conductive nanomaterials in developing conductive textiles. Different conductive nanomaterials, their advantages and disadvantages, their potential for improving conductivity of textiles and various applications of conductive textiles have been summarized in this review.

Keywords: Conductive textiles; CNT; Graphene; MXene; Nanocoating; Polymer nanocomposite

Introduction

Metallic filaments (such as steel, copper, aluminum etc.) and intrinsically conducting polymers (ICPs) such as polypyrrole (PPy), polyaniline (PANI), polyacetylene, polythiophene, poly(3,4- ethylenedioxythiophene)- poly(styrene sulfonate) (PEDOT:PSS) etc. are being used from a long run in conventional conductive textiles [1-3]. However, these conventional conductive textiles have many limitations. Recently, nanotechnology has offered growing interest for developing conductive smart textiles through the incorporation of active conductive nanomaterials in textiles [4-5]. Especially, increased attention has been given to different carbonbased nanomaterials (carbon nanotubes (CNTs) and graphene), metallic nanomaterials and MXene because of their high electrical and thermal conductivity. The recent developments in this field have been summarized in this review.

Conductive Nanofillers

Conductive metallic nanomaterials

Conductive metals (such as silver, copper, gold, aluminum, and tin) and metal oxide (TiO2 and ZnO) nanomaterials exhibit great promise as alternatives to conventional conductive materials [6-8]. These conductive metal nanomaterials (nanoparticles or nanowires) can be incorporated in different polymers to make conductive polymer nanocomposites, which can be used further for making conductive fibers or coated textiles. However, in polymer matrices, generally, metal nanowires exhibit better conductivity in comparison to metal nanoparticles because of their better conductive network at lower concentrations and less inter-particle junctions in the case of nanowires [9]. Conductive nanoparticles such Ag, ZnO and TiO2 dissipate the static charge of synthetic fibers because of their good electro-conductive property and hence, these nanoparticles can be used to develop antistatic fabrics [10-11].

Carbon-based nanomaterials

Different carbon-based nanomaterials such as 2D graphite and graphene, 1D CNTs, carbon black etc. are extensively used to increase conductivity of polymer and textiles [12-14]. The electrical conductivity, of pure CNT can be as high as 106 to 107 S m–1 and for pure graphene, it can be up to 105 S m–1. On the other hand, the thermal conductivity value of CNT may vary between 2800–6000 W m–1K–1 (in longitudinal direction), where for graphene it may be as high as 5000 W m–1K–1 [14]. Because of such high thermal and electrical conductivity, CNT and graphene have great potential for enhancing the conductive property of textiles. In an interesting study, Chen, et al. [15] studied the effect of different carbon-based nanomaterials and their aspect ratios on the thermal conductivity of epoxy nanocomposites, where the thermal conductivity increased with increasing filler concentration and aspect ratio. Moreover, graphene oxide (GO) showed the best thermal conductivity, while carbon black showed the most inferior performance [15].

MXene

MXene is a metal carbide or nitride-based emerging 2D nanomaterial with very high electrical conductivity up to 9880 S cm–1 [16-17]. It is represented with a general formula of Mn+1XnTx (where M is a transition metal, X is carbon and/or nitrogen, Tx represents the functional groups such as O, OH, Cl and F). MXene, especially Ti3C2Tx nanosheets have already been proven as an excellent electrode material because of its very high conductivity, large surface area, surface functionalities, rich physical and chemical properties, high specific capacitance and power density [17-18].

Recently Yan, et al. [16] prepared PPy–MXene coated textile by two-step method – (i) dipping of textile in MXene solution and drying, (ii) electrochemical deposition of PPy on MXene-textiles, resulting in very high specific capacitance of 343.20 F g−1, energy density of 1.30 mW h g−1 (power density = 41.1 mW g−1), which is much higher than the values reported in other studies for carbon nanotubes (CNTs) and active carbon, showing a good potential for supercapacitors, flexible and wearable energy storage devices [16].

Techniques for making conductive textile by incorporating nanomaterials

There are many techniques for making nano-enhanced conductive smart textiles. The different techniques for incorporation of conductive nanofillers in textiles are –

1. Finishing of textiles using conductive nanofillers by dip and dry method or layer-by-layer (LbL) deposition [19]

2. Nanocoating of conductive fillers on textiles by different techniques such as sputter coating, chemical vapor deposition (CVD), electroless plating etc. [20]

3. Coating of conductive polymer nanocomposites on textiles [16]

4. Use of conducting polymer nanocomposite fibers for making conductive yarn/fabric [18]

5. Preparation of polymer nanocomposite-based nanofibers by electrospinning process [21]

Applications of conductive textiles

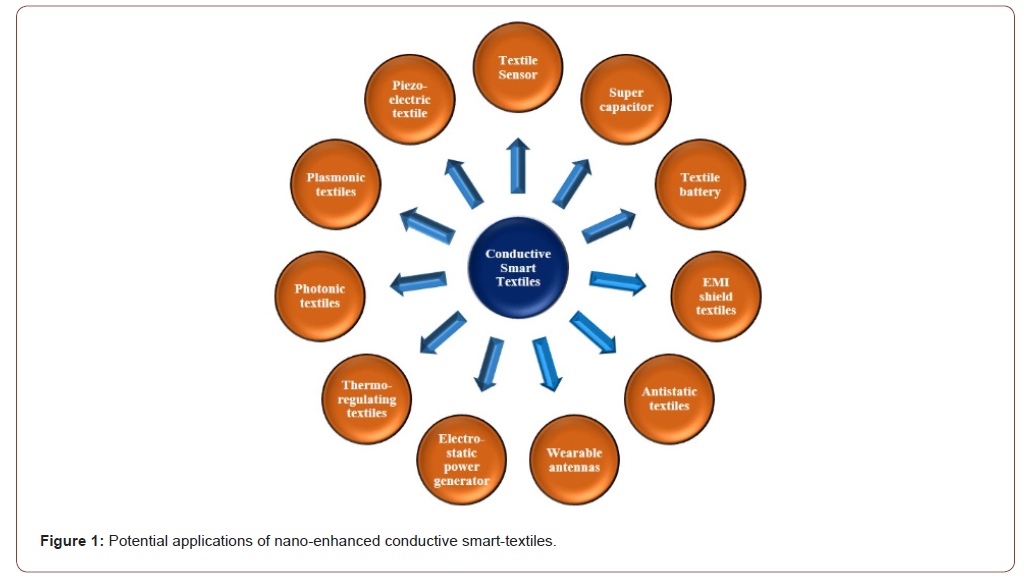

In conjugation with conductive nanomaterials, textiles offer many smart features for high-performance applications such as electroconductive textiles, EMI shield textiles, antistatic textiles, textile-sensors, textile batteries, supercapacitors, piezo-electric textiles, thermoregulating textiles, wearable antenna photonic textiles and many others [4,9,22], as summarized in Figure 1. Recently, conductive smart textiles have huge demand coving a wide range of application areas such as healthcare, sports, workwear and many other technical fields.

Conclusion

In summary, different conductive nanofillers have huge potential for enhancing the conductive property of materials which will drive the futuristic development of smarter conductive textiles for multi-direction applications.

To read more about this article....Open access Journal of Textile Science & Fashion Technology

Please follow the URL to access more information about this article

To know more about our Journals...Iris Publishers

No comments:

Post a Comment